David Savastano, Editor05.03.18

In 2016, Siegwerk Druckfarben AG & Co. KGaA announced its entry into the field of inkjet inks with its opening of an R&D laboratory for water-based and UV digital ink facility in Annemasse, France. In 2017, Siegwerk followed by launching a new digital ink manufacturing facility there.

Inkjet is a natural fit for the billion-dollar ink manufacturer, as digital printing is making inroads into packaging, driven by the demand for shorter runs, regionalization and personalization.

In a significant move, Siegwerk has acquired Agfa Graphics’ UV inkjet assets for the single pass packaging and labels industry, including a selected OEM customer list, IP and services. Agfa will continue its efforts in other digital ink segments.

“With this deal, we are bridging the best of two worlds. Agfa Graphics owns an incredible intellectual property in the domain of UV curable digital inks for packaging. While we will continue to rely on Agfa’s existing strong collaboration with OEMs and printhead manufacturers, we will be able to offer our packaging market access and application know-how to these new partners,” said Matthieu Carni, director Business Unit Inkjet Siegwerk.

Carni said that Siegwerk has had excellent success with its initial inkjet developments, and the addition of Agfa’s UV inkjet portfolio will be a big plus.

“We are looking back on a good past year with significant commercial success for our inkjet business,” Carni observed. “The acquisition of Agfa Graphics’ UV inkjet business for labels and packaging this year will definitively boost our business and bring it to the next level. We will now use Agfa’s inks portfolio as the backbone of our UV inks offer.”

Siegwerk’s R&D team has developed solutions designed for packaging as well, which the company will bring to its customers.

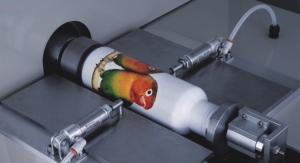

“We will add on top of the Agfa range some unique solutions previously developed by Siegwerk inkjet lab to bring an extended offer for many applications like self-adhesive labels for household, hygiene and industrial packaging, wet-glue labels for beverages, direct printing on 3D-packaging objects, blister and aluminum lids for pharma and food products,” Carni reported. “All our inkjet inks comply with relevant legislation and in particular with product safety requirements of NPH (Nutrition Pharmaceutics Hygiene) segment.”

For Siegwerk, the focus will be entirely on the packaging.

“Siegwerk is a global provider of printing inks for packaging applications and labels offering both analog and digital inks,” Carni reported. “We only investigate new market opportunities in the packaging and label printing segments. That’s why markets like textile, ceramic tile, display or decoration printing are not part of our business development activities for our digital printing solutions at all.

“From our perspective, the most promising technologies are UV and water-based inkjet, two areas we are already focusing our activities on since our move into digital printing a few years ago,” he added. “For UV inkjet we see great opportunity to become a mainstream printing technology for labels soon. UV inkjet is suitable for narrow web printing on thick material such as labels & direct-to-shape while water-based inkjet is appropriate for single pass large width printing for flexible packaging and paper & board applications.”

While there is a focus on UV inkjet due to the Agfa acquisition, Carni added that water-based inkjet is also an emphasis for Siegwerk.

“Our ongoing developments on water-based inkjet inks for packaging applications will continue and will be strengthened,” he noted. “Water-based inkjet inks are naturally offering great opportunities for corrugated printing applications. We expect this technology to also become the technology of choice for digital printing of flexible packaging, even if there are still some significant technology barriers that need to be overcome first.”

Carni sees excellent opportunities ahead for digital printing in the labels and packaging, with labels continuing being an earlier adopter of the technology.

“Going forward, we will see a continuously increasing demand for short-runs, regionalization, personalization and special finishing of packaging, which will further drive the growth of digital printing technologies, including both electrophotography and UV inkjet solutions,” Carni said. “The need for brand differentiation and lean production cycles will also drive the digital trend in the future printing industry. Digital printing inks for labels will gain strong traction while digital inks for packaging will further progress going forward.”

Source: Siegwerk

Inkjet is a natural fit for the billion-dollar ink manufacturer, as digital printing is making inroads into packaging, driven by the demand for shorter runs, regionalization and personalization.

In a significant move, Siegwerk has acquired Agfa Graphics’ UV inkjet assets for the single pass packaging and labels industry, including a selected OEM customer list, IP and services. Agfa will continue its efforts in other digital ink segments.

“With this deal, we are bridging the best of two worlds. Agfa Graphics owns an incredible intellectual property in the domain of UV curable digital inks for packaging. While we will continue to rely on Agfa’s existing strong collaboration with OEMs and printhead manufacturers, we will be able to offer our packaging market access and application know-how to these new partners,” said Matthieu Carni, director Business Unit Inkjet Siegwerk.

Carni said that Siegwerk has had excellent success with its initial inkjet developments, and the addition of Agfa’s UV inkjet portfolio will be a big plus.

“We are looking back on a good past year with significant commercial success for our inkjet business,” Carni observed. “The acquisition of Agfa Graphics’ UV inkjet business for labels and packaging this year will definitively boost our business and bring it to the next level. We will now use Agfa’s inks portfolio as the backbone of our UV inks offer.”

Siegwerk’s R&D team has developed solutions designed for packaging as well, which the company will bring to its customers.

“We will add on top of the Agfa range some unique solutions previously developed by Siegwerk inkjet lab to bring an extended offer for many applications like self-adhesive labels for household, hygiene and industrial packaging, wet-glue labels for beverages, direct printing on 3D-packaging objects, blister and aluminum lids for pharma and food products,” Carni reported. “All our inkjet inks comply with relevant legislation and in particular with product safety requirements of NPH (Nutrition Pharmaceutics Hygiene) segment.”

For Siegwerk, the focus will be entirely on the packaging.

“Siegwerk is a global provider of printing inks for packaging applications and labels offering both analog and digital inks,” Carni reported. “We only investigate new market opportunities in the packaging and label printing segments. That’s why markets like textile, ceramic tile, display or decoration printing are not part of our business development activities for our digital printing solutions at all.

“From our perspective, the most promising technologies are UV and water-based inkjet, two areas we are already focusing our activities on since our move into digital printing a few years ago,” he added. “For UV inkjet we see great opportunity to become a mainstream printing technology for labels soon. UV inkjet is suitable for narrow web printing on thick material such as labels & direct-to-shape while water-based inkjet is appropriate for single pass large width printing for flexible packaging and paper & board applications.”

While there is a focus on UV inkjet due to the Agfa acquisition, Carni added that water-based inkjet is also an emphasis for Siegwerk.

“Our ongoing developments on water-based inkjet inks for packaging applications will continue and will be strengthened,” he noted. “Water-based inkjet inks are naturally offering great opportunities for corrugated printing applications. We expect this technology to also become the technology of choice for digital printing of flexible packaging, even if there are still some significant technology barriers that need to be overcome first.”

Carni sees excellent opportunities ahead for digital printing in the labels and packaging, with labels continuing being an earlier adopter of the technology.

“Going forward, we will see a continuously increasing demand for short-runs, regionalization, personalization and special finishing of packaging, which will further drive the growth of digital printing technologies, including both electrophotography and UV inkjet solutions,” Carni said. “The need for brand differentiation and lean production cycles will also drive the digital trend in the future printing industry. Digital printing inks for labels will gain strong traction while digital inks for packaging will further progress going forward.”

Source: Siegwerk