David Savastano, Editor03.01.18

Food packaging is the most heavily regulated mainstream area for ink manufacturers, and rightfully so, as packaging can possibly impact the foods that are consumed.

In the case of Colorcon No-Tox® Products, food packaging requirements are even more stringent, as the ink can be printed directly on packaging that comes in direct contact with food.

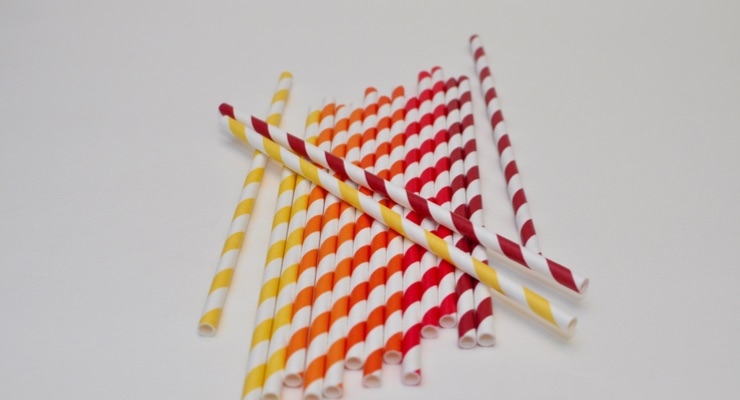

“Colorcon inks can be found in direct contact with many leading products used by consumers on a daily basis,” said Knut Fenner, GM at Colorcon No-Tox Products. “From inside-printing on yoghurt-lids to chocolate and candy wrappers, from direct-food contact surfaces of fast food containers to tray liners to pet food packaging, our inks are chosen for their compliance with FDA raw material requirements and the manufacturing processes Colorcon has implemented to guarantee the highest safety and quality for our customers.”

Not surprisingly, Colorcon offers the latest quality standards, using only FDA compliant raw materials, manufacturing according to current Good Manufacturing Practices (cGMP) and employing an ISO 9001:2015 registered QMS system, which the company earned recently.

“Adding an ISO 9001:2015 registered quality management system demonstrates to customers and suppliers alike that our internal quality processes operate according to highest international quality standards,” Fenner observed.

Fenner added that for an ink company specializing in the development and manufacturing of FDA and EU compliant direct and indirect food contact printing inks, having the proper safety, quality, regulatory and compliance regulations in place is imperative to doing business.

“Colorcon uses only FDA compliant raw materials in the development and manufacturing of its products,” he noted. “Having registered our facility with the FDA, essentially allowing the FDA to audit our manufacturing facility at any time, assures our customers of our uncompromising commitment to safety. Manufacturing under FDA enforced current Good Manufacturing Practices (cGMP) means that as a manufacturer, we must employ technologies and systems which are up-to-date in order to comply with FDA regulations under Title 21 CFR. Because of this high-level commitment to safety and quality, Colorcon No-Tox Products has been the go-to company for direct food contact (DFC) inks for the past 50 years.”

There are no real certifications or requirements needed for manufacturers of conventional inks to do business. Fenner noted that ink companies may choose to get ISO 9001 registered, but it is not a must. There have been well-publicized instances of food packaging ink that has migrated into the food, causing recalls and lots of negative publicity. As a result, brand owners that use direct food contact inks require assurances that the inks they use are safe.

“As a specialist in FDA and EU compliant direct food contact inks, quality and safety are paramount to us and our customers,” he reported. “It is for that reason that we went through the unusual steps of combining all three designations for the benefit of our customers. We even take it a step further and guarantee FDA and/or EU compliance in writing for each batch that we manufacture in writing.”

To that end, Fenner said that Colorcon puts in extra effort on the regulatory front and is well equipped to help customers in the area of direct and indirect food contact.

“Colorcon provides its customers not only with FDA and EU compliant printing inks but also with regulatory advice, an area where we have developed significant expertise over the last 50 years,” he said. “Many of our customers consult with us prior to making ink choices in order to make sure they understand the regulatory environment of the markets they target for their products. Colorcon is directly or indirectly involved with most of the leading regulatory agencies and bodies around the world in order to stay current on the developments in those markets.”

Source: Colorcon No-Tox Products

In the case of Colorcon No-Tox® Products, food packaging requirements are even more stringent, as the ink can be printed directly on packaging that comes in direct contact with food.

“Colorcon inks can be found in direct contact with many leading products used by consumers on a daily basis,” said Knut Fenner, GM at Colorcon No-Tox Products. “From inside-printing on yoghurt-lids to chocolate and candy wrappers, from direct-food contact surfaces of fast food containers to tray liners to pet food packaging, our inks are chosen for their compliance with FDA raw material requirements and the manufacturing processes Colorcon has implemented to guarantee the highest safety and quality for our customers.”

Not surprisingly, Colorcon offers the latest quality standards, using only FDA compliant raw materials, manufacturing according to current Good Manufacturing Practices (cGMP) and employing an ISO 9001:2015 registered QMS system, which the company earned recently.

“Adding an ISO 9001:2015 registered quality management system demonstrates to customers and suppliers alike that our internal quality processes operate according to highest international quality standards,” Fenner observed.

Fenner added that for an ink company specializing in the development and manufacturing of FDA and EU compliant direct and indirect food contact printing inks, having the proper safety, quality, regulatory and compliance regulations in place is imperative to doing business.

“Colorcon uses only FDA compliant raw materials in the development and manufacturing of its products,” he noted. “Having registered our facility with the FDA, essentially allowing the FDA to audit our manufacturing facility at any time, assures our customers of our uncompromising commitment to safety. Manufacturing under FDA enforced current Good Manufacturing Practices (cGMP) means that as a manufacturer, we must employ technologies and systems which are up-to-date in order to comply with FDA regulations under Title 21 CFR. Because of this high-level commitment to safety and quality, Colorcon No-Tox Products has been the go-to company for direct food contact (DFC) inks for the past 50 years.”

There are no real certifications or requirements needed for manufacturers of conventional inks to do business. Fenner noted that ink companies may choose to get ISO 9001 registered, but it is not a must. There have been well-publicized instances of food packaging ink that has migrated into the food, causing recalls and lots of negative publicity. As a result, brand owners that use direct food contact inks require assurances that the inks they use are safe.

“As a specialist in FDA and EU compliant direct food contact inks, quality and safety are paramount to us and our customers,” he reported. “It is for that reason that we went through the unusual steps of combining all three designations for the benefit of our customers. We even take it a step further and guarantee FDA and/or EU compliance in writing for each batch that we manufacture in writing.”

To that end, Fenner said that Colorcon puts in extra effort on the regulatory front and is well equipped to help customers in the area of direct and indirect food contact.

“Colorcon provides its customers not only with FDA and EU compliant printing inks but also with regulatory advice, an area where we have developed significant expertise over the last 50 years,” he said. “Many of our customers consult with us prior to making ink choices in order to make sure they understand the regulatory environment of the markets they target for their products. Colorcon is directly or indirectly involved with most of the leading regulatory agencies and bodies around the world in order to stay current on the developments in those markets.”

Source: Colorcon No-Tox Products