05.18.18

Grafinpack, an Italian folding carton manufacturer, installed an Scodix E106 Enhancement Press.

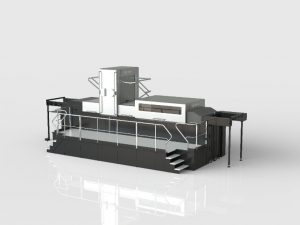

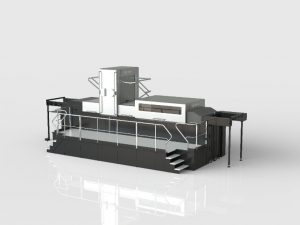

Showcased at drupa 2016, the Scodix E106 was developed specifically to deliver digital enhancement solutions to folding carton converters needing a B1 (1060 x 760mm or 41.7 x 29.9inch) format.

“We carried out an ROI study which indicated that the Scodix E106 could deliver significant savings on 80% of our jobs in comparison with our existing process of hot-foiling in-house,” said Manuel Turini, managing director at Grafinpack.“The business has to be cost effective, but print quality is equally important to us and our customers, Scodix technology opens up new possibilities for improvement in both facets.

“The Scodix E106 will serve our existing enhancement needs as well as allowing us to take on new work and create new enhancement effects,” Turini added. “This is an important stage in our company’s evolution and we realized that the time is now to invest in the technology, in order to stay ahead of our competitors.”

Scodix Head of Packaging, Nigel Tracey said: “Scodix is on a mission to emulate its success from the commercial digital print sector in the folding carton industry. Having installed over 300 Scodix presses during the last eight years, Scodix now has the right technology and format for folding carton enhancement, following five years of rigorous development and testing. The result is the Scodix E106 which offers customers totally new applications and an overall more efficient way to produce their existing range of carton enhancements.

“Be it foil, spot varnish, or high build UV effects, the Scodix E106 can replace multiple analogue machines, four in one,” Tracey added. “It’s for these reasons that Grafinpack decided to invest in the Scodix E106 to become one of the first carton makers to benefit from this new technology. Already we are seeing some of the ways they are exploiting the Scodix E106 to enhance their current assortment of work.”

Showcased at drupa 2016, the Scodix E106 was developed specifically to deliver digital enhancement solutions to folding carton converters needing a B1 (1060 x 760mm or 41.7 x 29.9inch) format.

“We carried out an ROI study which indicated that the Scodix E106 could deliver significant savings on 80% of our jobs in comparison with our existing process of hot-foiling in-house,” said Manuel Turini, managing director at Grafinpack.“The business has to be cost effective, but print quality is equally important to us and our customers, Scodix technology opens up new possibilities for improvement in both facets.

“The Scodix E106 will serve our existing enhancement needs as well as allowing us to take on new work and create new enhancement effects,” Turini added. “This is an important stage in our company’s evolution and we realized that the time is now to invest in the technology, in order to stay ahead of our competitors.”

Scodix Head of Packaging, Nigel Tracey said: “Scodix is on a mission to emulate its success from the commercial digital print sector in the folding carton industry. Having installed over 300 Scodix presses during the last eight years, Scodix now has the right technology and format for folding carton enhancement, following five years of rigorous development and testing. The result is the Scodix E106 which offers customers totally new applications and an overall more efficient way to produce their existing range of carton enhancements.

“Be it foil, spot varnish, or high build UV effects, the Scodix E106 can replace multiple analogue machines, four in one,” Tracey added. “It’s for these reasons that Grafinpack decided to invest in the Scodix E106 to become one of the first carton makers to benefit from this new technology. Already we are seeing some of the ways they are exploiting the Scodix E106 to enhance their current assortment of work.”