35 Waterview Blvd.

Parsippany, NJ 07054

Phone: (973) 404-6000

Fax: (973) 404-6001

Sales: Sun Chemical had annual sales of $3.5 billion in printing inks and colorants worldwide. North American Ink Sales: $1.5 billion (Ink World estimate).

Major Products: Broad product portfolio with capabilities in web heatset and sheetfed offset; publication and packaging gravure; news ink and publication coldset; flexographic packaging inks; corrugated packaging inks; energy curable inks and coatings; screen inks, label and narrow web inks, toner, inkjet materials, adhesives for packaging, overprint varnishes, specialty coatings, effect inks, flexographic printing plates, digital artwork file management, color software and brand color management, printed electronics, security inks and coatings, and organic colorants for inks, plastics, paints, coatings and cosmetics.

(2).jpg) |

Key Personnel: Rudi Lenz, president and CEO, Sun Chemical and Board member

Key Leaders (in alphabetical order): Martin Cellerier, VP, corporate strategy; Robert Fitzka, group managing director, Europe Central Region; John Gowlett, VP, global operations; Greg Hayes, group managing director, Europe Northern Region; Gregory Lawson, president, Sun Chemical Latin America; John McKeown, senior VP, chief administration officer; Felipe Mellado, chief marketing officer and Board member; Charles Murray, president, North American Inks; Carlo Musso, group managing director, Europe Southern Region; Myron Petruch, president, Performance Pigments; Bradley Schrader, VP, corporate planning; Edward Pruitt, chief procurement officer; Russell Schwartz, chief technology officer; Mehran Yazdani, GM DIC America & Electronic Materials.

Number of Employees: More than 8,000 worldwide.

Operating Facilities: Sun Chemical has more than 300 manufacturing and service locations worldwide and more than 200 customer in-plant locations in the U.S. alone.

Comments: Sun Chemical had a comparable year to 2011, as the company continued to recover volume in all of its sectors, but the company continues to face the same challenges as it moves ahead.

In particular, Charles Murray, president, North American Inks for Sun Chemical, noted that the publication and commercial sheetfed markets continue to struggle, adding that the shift in the publications market has been drastic. “Sales in this market have not recovered to pre-recession levels and we don’t expect that they will,” Mr. Murray said.

By contrast, Mr. Murray reported that Sun Chemical enjoyed moderate growth in 2012, led by flexible packaging, and the company is working with brand owners and major packaging groups to provide solutions for specialized packaging. He added that Sun Chemical will continue to see growth in the flexible packaging segment, particularly in value-added packaging, as the market moves toward functional and sensory packaging. He believes that further growth will come from the narrow web, tag, and label businesses, as well as the folding carton segment.

To meet the needs of their customers, Sun Chemical is investing in manufacturing, processes and products, despite the challenging economy.

In July, Sun Chemical Performance Pigments acquired Benda-Lutz Werke GmbH, a leading manufacturer of metallic effect products based in Austria. The acquisition allows Sun Chemical to purchase 100% of the shares, assets and business from Benda-Lutz and would expand its product portfolio in metallic effects. With the acquisition, Sun Chemical adds production facilities in Austria, Poland, Russia and the U.S. to accompany its aluminum pigment manufacturing site in China, forming the basis of a new global Metallics Business Unit as part of Sun Chemical’s Performance Pigments Division.

The company also opened two major new facilities. In June, Sun Chemical reinforced its commitment to customers in Montreal and the Province of Quebec with the opening of its new 50,000 square foot state-of-the-art ink manufacturing plant in Laval, a $3.1 million (CAD) investment designed to provide stronger customer service, improve efficiency and reduce costs.

The new facility consolidates four manufacturing plants located in Ottawa, Quebec City and two buildings located in the Montreal suburbs of Boucherville and Anjou.

Also in 2012, Sun Chemical invested $9.1 million to build a brand new printing ink manufacturing plant in San Bernardo, Chile, a suburb of Santiago. Primarily a manufacturer of packaging inks, the facility is expected to produce 10,500 tons of inks annually that serve its principal domestic customers as well as other locations across South America, including Brazil and Argentina.

Sun Chemical received numerous honors this year. In September, Sun Chemical’s UK and Ireland Customer Service Center, based in Trafford Park, was awarded the 2012 Customer Service Excellence Award by the British Printing Industries Federation (BPIF). The BPIF awards are intended to reward and showcase the most innovative and creative companies across the print media spectrum and are recognized as the benchmark for business acumen in the print sector.

Other honors went to Edward Pruitt, Sun Chemical’s chief procurement officer, as the “2012 Man of the Year” by the Metro New York Printing Ink Association. Moe Rahmeh, a technical manager for Sun Chemical in the Dallas/Fort Worth region, received the 2012 National Association of Print Ink Manufacturers (NAPIM) Printing Ink Pioneer Award, which honors longevity and service in the print industry, committee work, technical contributions and service to associations.

In terms of raw materials, Mr. Pruitt noted that while Sun Chemical has not experienced this year the widespread shortages and allocations that plagued the industry two years ago, the raw material supply chain is a continuing concern to Sun Chemical.

“A sharp uptick in demand from the emerging markets or developed economies could quickly put products like titanium dioxide, nitrocellulose, carbon black and some pigments in very tight inventory positions,” Mr. Pruitt said. “We also need to be mindful of the potential impact of global weather conditions on such raw materials as gum rosin, ethanol and vegetable oils.

“In general, at Sun Chemical we see a continuation of the current moderation trend in the raw materials market this year,” Mr. Pruitt added. “This outlook is based on the assumption that the tepid economic performance that is being seen in North America, Europe and in Asia will continue for the last quarter of this year. The great wild card here is the price of oil, which has regained strength. If prices do not retrench, it will start to drive the cost of oil and petrochemical derivatives upward.”

Sun Chemical launched a number of new products this year. In July, Sun Chemical was awarded an InterTech Technology Award, one of the highest honors in the printing industry, for its SunPak LMQ (low migration quality) products. Awarded annually by the Printing Industries of America, the InterTech Award recognizes the development of unique and innovative technologies that are predicted to have a significant impact on the graphic arts and related industries.

Sun Chemical’s SunPak LMQ products help address the risk brand owners face in packaging, where compounds from materials in the packaging structure can migrate into the food product or the surrounding environment. SunPak LMQ inks exhibit very low odor, off-flavor and migration levels, and offer a comprehensive solution to brand owners and converters who are looking for ways to address migration concerns for food, pharmaceutical and tobacco applications.

Sun Chemical retired its SmartColour brand from the marketplace and transferred all current customer licenses to the new PantoneLIVE eco-system from X-Rite/Pantone. PantoneLIVE licensees can take advantage of Sun Chemical’s intellectual property in the field of digital color communication.

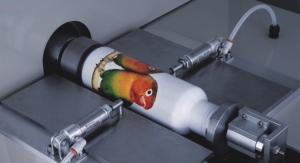

In July, Sun Chemical launched the SunUno Solimax multi-purpose ink system. Suitable for both surface and reverse print applications on a number of the commonly used flexible packaging substrates, Solimax will maximize print run efficiency while simplifying overall print production. It is suitable for both flexo and gravure printing. In September, Sun Chemical launched SunLit Crystal, an “all-in-one” universal sheetfed offset process ink set.

SunJet, the inkjet ink division of Sun Chemical, launched its JetStream PCO Oil-based HD Black ink for Seiko Instruments Inc. printheads. The JetStream PCO HD Black has been developed with high performance pigment and drop spread control technology to meet the needs for high contrast and high definition printing demanded in applications such as bar coding, stock identification and decoration.

During Labelexpo Americas 2012, SunJet also launched EtiJet LM UV, its new low migration UV curing ink range for the digital label market, suitable for all types of piezo printheads. All of the ink components appear on the European positive lists, Swiss Ordinance and EuPIA, and the inks do not use materials specifically excluded in the Nestle list, meaning the inks meet the highest industry standards for food packaging.

In July, Sun Chemical launched Streamline ESL HPQ and Streamline Ultima HPQ, designed for use in wide and super-wide format printers using high-quality solvent-based inks.

During Labelexpo Americas 2012, Sun Chemical featured its Solaris System, a complete line of inks and coatings designed to meet all the printing needs of all narrow web and packaging printers. The full range includes products for virtually all narrow web applications from self-adhesive and in-mold labels to wrap arounds, shrink sleeves, tubes and food and pharmaceutical packaging.

At SuperCorr, Sun Chemical showcased its SunVisto Advantage line of water-based inks. Specifically developed to be pH stable for corrugated printers who want a consistent press run without monitoring or adjusting pH levels, the inks offer consistent color strength, longer press runs without maintenance and reduced plate washing during a press run. Also at SuperCorr were SunVisto Hydroking PHS water-based inks.

At INFO*FLEX 2012, Sun Chemical highlighted SunSpectro Sunsharp solvent-based inks. Developed for high-speed, wide web flexo presses for bread bags and frozen food packaging, SunSpectro Sunsharp inks are high gloss, resistant to water, fats and oils, and formulated for low odor and low viscosity for enhanced color strength. Developed for flexographic printing on polyethylene film, SunSpectro Sunsharp HR solvent-based inks provide moderate heat resistance of up to 350 degrees, maintain excellent gloss and are suitable for printing on items such as plastic bags, shampoo bottles and milk containers.

Sun Chemical highlighted its anti-counterfeiting solutions to help brand owners ensure the integrity of their packaging. Sun Chemical offers a variety of security ink solutions including an infrared coding solution called Verigard, a security system that adds a small quantity of taggants, or chemical markers, to inks, varnishes or coatings for use in any print process on any substrate.

In October, Sun Chemical demonstrated its Vitrocure UV curing ink from the SunVetro range at Glasstec 2012 in Dusseldorf. The SunVetro range of inks prints bright and strong colors that would be difficult to achieve with inorganic inks.

During the SNEC 2012 PV Power Expo and the European Photovoltaic Solar Energy Conference and Exhibition, the Sun Chemical Electronic Materials division showed how photovoltaic manufacturers can save money by taking advantage of Sun Chemical’s unique one-stop shop offering, including a broad range of metallization solutions for both additive and subtractive processes as well as module materials for use in the crystalline silicon (c-Si), thin film, printed electronics, and other emerging markets.