David Savastano, Editor07.18.19

As designers discover the benefits of digital textile printing, the technology is being used for more applications. Industry leaders see opportunities ahead, from custom printed T-shirts and sportswear to fast fashion.

Tony Cox, business manager, Sun Chemical, noted that printed textiles have traditionally been featured across many markets, from carpets to apparel and home furnishing to soft signage, and all of these markets have usually used screen printing techniques over the years.

“These markets continue to be strong with an excellent growth forecast over the coming years,” Cox added. “This growth has been energized by the adoption of digital printing in the textile market and has created some new and exciting opportunities.”

Tim Check, senior product manager, Professional Imaging, Epson America, Inc., said that apparel is a massive market opportunity that is mostly (95%) produced using the traditional screenprinting process.

“While the retail side of the business is beginning to embrace digital on-demand production to lower operational costs, there is still a disconnect with designers,” Check reported. “As designers become aware of the limited constraints with digital printing, I expect that we will see a greater increase in fashion apparel produced digitally.”

David Lopez, textile solutions specialist at Mimaki USA, also pointed to digital printing’s ability to compete with screenprinting.

“Digital printing technology keeps taking big strides forward to increase speeds to match up to its predecessor of screenprinting,” Lopez observed.

Dr. Simon Daplyn, marketing manager, Sensient Imaging Technologies, noted that sportswear is a market that has the potential to benefit greatly from digital printing.

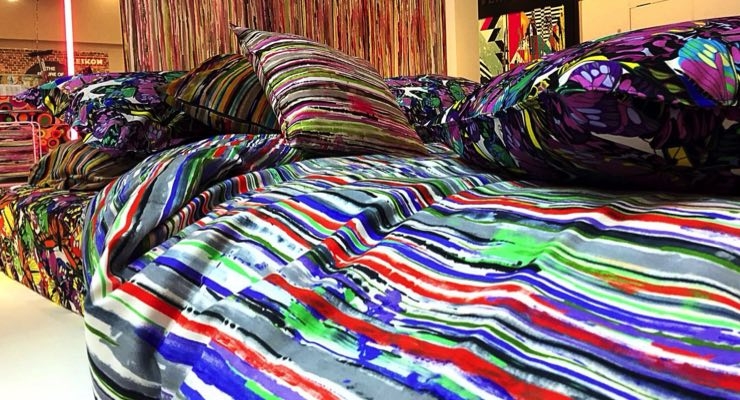

“With digital inks, sportswear manufacturers can achieve intricate, vibrant designs on both polyester and polyamide, while using more environmentally responsible inks,” said Dr. Daplyn. “Vibrancy and functionality are key when it comes to printing interior fabrics, furnishings and flooring and home textiles is another area that is starting to benefit from digital printing.”

Micol Gamba, textile product manager for EFI Reggiani, said sustainability is an area where digital printing will thrive.

“About sustainability, our focus is not only on printers but on complete green solutions to shorten traditional textile process steps and reduce water and energy consumption,” said Gamba. “EFI Reggiani pigment and direct sublimation solutions are really going into this direction, for textile processes with a limited environmental footprint.”

Lily Hunter, product manager, textiles and consumable supplies – Roland DGA, observed that as printers continue to improve on print quality and speed, and customized goods become increasingly popular, digital printing will continue to grow in various textile applications.

“Custom printed T-shirts are extremely popular,” Hunter added. “Digital textile printing isn’t limited to dye-sublimation technologies or pigment printing devices. It includes other ink technologies as well. There are so many new options for fabrics; for instance, polyester made to mimic linen, silk, and cotton, so it can be dye-sublimated. There are also faux leather products that can be printed with UV inks to produce beautiful accessories and décor.”

Hamid Shirazi, Ph.D., segment marketing manager, FUJIFILM Ink Solutions, Ltd., noted that the greatest driver is the turnaround speed.

“We can see the transition from having one or two seasons per year, but now you can actually have fast fashion, which means you can introduce new fashion into the market every two or three weeks,” Dr. Shirazi added. “As a whole, the market has really changed with the advantage of digital printing. In particular, if you look at different segments, there are traditional printers who typically do the bigger jobs, but they now have the capability of doing much shorter jobs and doing it on demand. Within the original supply chain there’s a lot more capability, but also within the new supply chain you can see digital printing moving closer and closer to the end-users and retailers. That is connecting the consumer much more to the product.

“You see the ultimate connection in terms of e-commerce where the consumer is also the designer,” Dr. Shirazi pointed out. “If you go online and put in a design, you can print that and have that delivered to you within 48 to 72 hours. It’s a new market that didn’t exist before, not only is digital printing helping to grow the existing part of the market and giving them a lot more flexibility, but it’s also new markets that didn’t exist before.”

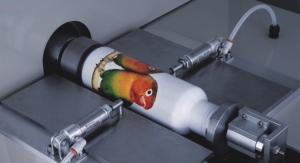

Source: EFI

Tony Cox, business manager, Sun Chemical, noted that printed textiles have traditionally been featured across many markets, from carpets to apparel and home furnishing to soft signage, and all of these markets have usually used screen printing techniques over the years.

“These markets continue to be strong with an excellent growth forecast over the coming years,” Cox added. “This growth has been energized by the adoption of digital printing in the textile market and has created some new and exciting opportunities.”

Tim Check, senior product manager, Professional Imaging, Epson America, Inc., said that apparel is a massive market opportunity that is mostly (95%) produced using the traditional screenprinting process.

“While the retail side of the business is beginning to embrace digital on-demand production to lower operational costs, there is still a disconnect with designers,” Check reported. “As designers become aware of the limited constraints with digital printing, I expect that we will see a greater increase in fashion apparel produced digitally.”

David Lopez, textile solutions specialist at Mimaki USA, also pointed to digital printing’s ability to compete with screenprinting.

“Digital printing technology keeps taking big strides forward to increase speeds to match up to its predecessor of screenprinting,” Lopez observed.

Dr. Simon Daplyn, marketing manager, Sensient Imaging Technologies, noted that sportswear is a market that has the potential to benefit greatly from digital printing.

“With digital inks, sportswear manufacturers can achieve intricate, vibrant designs on both polyester and polyamide, while using more environmentally responsible inks,” said Dr. Daplyn. “Vibrancy and functionality are key when it comes to printing interior fabrics, furnishings and flooring and home textiles is another area that is starting to benefit from digital printing.”

Micol Gamba, textile product manager for EFI Reggiani, said sustainability is an area where digital printing will thrive.

“About sustainability, our focus is not only on printers but on complete green solutions to shorten traditional textile process steps and reduce water and energy consumption,” said Gamba. “EFI Reggiani pigment and direct sublimation solutions are really going into this direction, for textile processes with a limited environmental footprint.”

Lily Hunter, product manager, textiles and consumable supplies – Roland DGA, observed that as printers continue to improve on print quality and speed, and customized goods become increasingly popular, digital printing will continue to grow in various textile applications.

“Custom printed T-shirts are extremely popular,” Hunter added. “Digital textile printing isn’t limited to dye-sublimation technologies or pigment printing devices. It includes other ink technologies as well. There are so many new options for fabrics; for instance, polyester made to mimic linen, silk, and cotton, so it can be dye-sublimated. There are also faux leather products that can be printed with UV inks to produce beautiful accessories and décor.”

Hamid Shirazi, Ph.D., segment marketing manager, FUJIFILM Ink Solutions, Ltd., noted that the greatest driver is the turnaround speed.

“We can see the transition from having one or two seasons per year, but now you can actually have fast fashion, which means you can introduce new fashion into the market every two or three weeks,” Dr. Shirazi added. “As a whole, the market has really changed with the advantage of digital printing. In particular, if you look at different segments, there are traditional printers who typically do the bigger jobs, but they now have the capability of doing much shorter jobs and doing it on demand. Within the original supply chain there’s a lot more capability, but also within the new supply chain you can see digital printing moving closer and closer to the end-users and retailers. That is connecting the consumer much more to the product.

“You see the ultimate connection in terms of e-commerce where the consumer is also the designer,” Dr. Shirazi pointed out. “If you go online and put in a design, you can print that and have that delivered to you within 48 to 72 hours. It’s a new market that didn’t exist before, not only is digital printing helping to grow the existing part of the market and giving them a lot more flexibility, but it’s also new markets that didn’t exist before.”

Source: EFI