Anthony Locicero, Associate Editor07.03.19

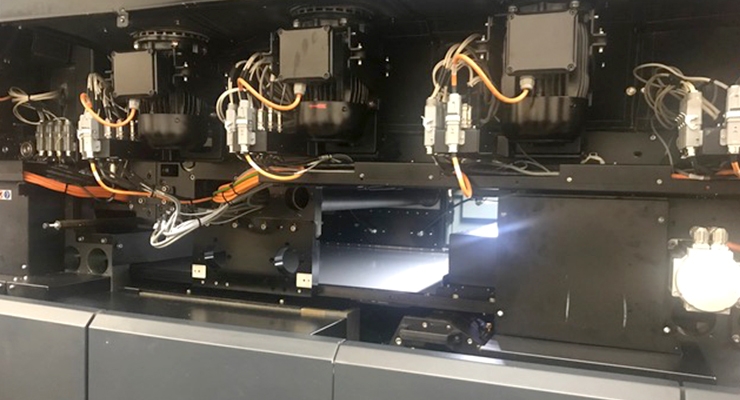

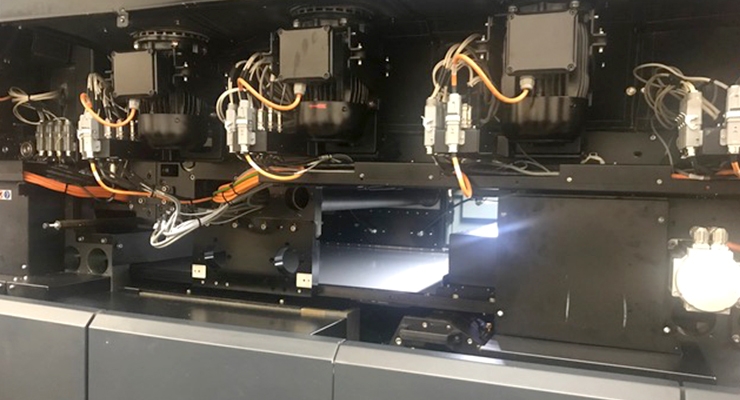

Mercury Print Productions CEO John Place beamed with pride as he talked about his company's newest install – the Landa S10P Nanographic print press.

"This press is going to change the way we do business," he told attendees during the June 27 open house at his 180,000-square-foot Rochester, NY facility.

"There are so many applications for this press," Place said, adding that the S10P will eliminate the need for a toner machine. "The greens and the blues are just popping off the sheet. We see ourselves purchasing another one."

Felix Medero, Mercury's director of Process Development, was wowed by the consistency from start to finish on the print jobs – especially compared to toner.

"There's very, very little movement," he noted. "The color is out of the box. We have not profiled that machine to the paper yet. There's been no characterization yet."

This 41-inch press prints 6,500 sheets per hour. While Mercury's bread and butter is printing educational books for clients such as McGraw-Hill and Houghton Mifflin Harcourt, Place said he'd like to go after packaging with the S10P.

Nanography is a Landa developed technology using nanoparticles. Nano-ink is characterized by ultra-thin dots of extremely high uniformity (

0.5 microns

), according to Nachum Korman, GM, Americas at Landa.

The process is to eject billions of Landa nano-ink droplets onto a heated blanket, dry the ink to form an image, and then transfer the image to the substrate, Korman explained.

With CMYK in offset, users only access 64% of the color gamut, Korman said. But with four color nano, it's 84% – 96% with seven-color.

What's unique about the nano-ink is that it contains the same pigments as dry ink – only half the amount of the ink itself is being used, Landa's VP of Products Strategy Gilad Tzori said.

"The ink is probably the most important part for Landa," Tzori emphasized. "Everything is built around the ink."

While he noted that the ink manufacturing is a "very confidential" process, Tzori shared the inks are very stable because they are water-based.

"The [nano]-ink itself is a huge game changer," he said. "Nano pigments enable us to get the same or better results with less amount of ink. That's a dramatic economic advantage."

Because the press drops the ink onto the blanket and it is completely dry, Tzori said, it enables users to work with any substrate and "get amazing results, coated or uncoated."

At Landa's Israeli headquarters, there are four plants and an R&D facility.

Presses are being assembled in Plant 1. There are six assembled presses in Plant 2. Plant 3 is under construction but will house the manufacturing of inks and consumables. Machines production is expected to begin in 2020 in Plant 4.

Korman said that press operators receive training online and then in person at Landa. The company sends an instructor to the install site to assist – and there is also an Israel-based support hotline.

According to Korman, 13 presses have been installed or will be installed globally – in the US (The S10P beta with a perfector at Mercury is the first US install of the press, completed in the spring), China, Germany, UK, France and Switzerland.

The company also plans to focus on Mexico before expanding into Brazil and other parts of South America, the GM said.

Landa is still growing, Korman said, as the company plans to add more service engineers as more presses are being installed.

"The future is already here," he exclaimed.