09.25.18

HP Inc. at Labelexpo Americas 2018 (booths 3226 and 3429) will demonstrate its latest innovations across the HP Indigo Digital Press portfolio.

“Digital adoption is growing, and converters need more sophisticated solutions to differentiate themselves and effectively add value to brands,” said Dave Prezzano, VP and GM, Graphics Solutions Business, Americas, HP Inc. “HP Indigo’s platform for digital labels and packaging production empowers converters to embrace the possibilities of print to create, innovate, and grow their business profitably. By optimizing supply chain and meeting sustainability goals all while helping brands engage with their consumers with state-of-the-art automated design and production management tool – HP Indigo is helping them, and their customers, thrive in a changing world.”

During the last year, the second dedicated shrink-sleeve HP Indigo 8000 was installed in the U.S. for serving the fast-growing craft beverage market.

In the last year, tens of millions of laminate tubes were printed using HP Indigo presses, including a major Korean cosmetic brand that moved production to digital for anti-counterfeiting and consumer.

HP Indigo GEM Enters First Stage of Beta Customer Testing

At Labelexpo 2017, the company announced HP Indigo GEM, the one-pass digital embellishments solution. This year, the HP Indigo GEM is in the first stage of beta customer testing and the first U.S. beta customer is Innovative Labeling Solutions.

“The HP Indigo GEM is a dramatic revolution in digital printing industry enabling us to bring a fully digital printing solution, including embellishments, to the marketplace,” said Jay Dollries, CEO, Innovative Labeling Solutions. “The cutting-edge technology delivered by HP Indigo GEM removes limitations allowing for embellishments to vary across labels further helping our business to be dynamic and responsive to deliver a broad range applications and creative capabilities.”

HP is also collaborating with LEONHARD KURZ Stiftung & Co. KG, a provider of foils, to ensure compatibility of its products with HP Indigo GEM. Additional compatible foils will be available from K Laser Technology.

HP Indigo 6900 Latest Capabilities

HP Indigo 6900:

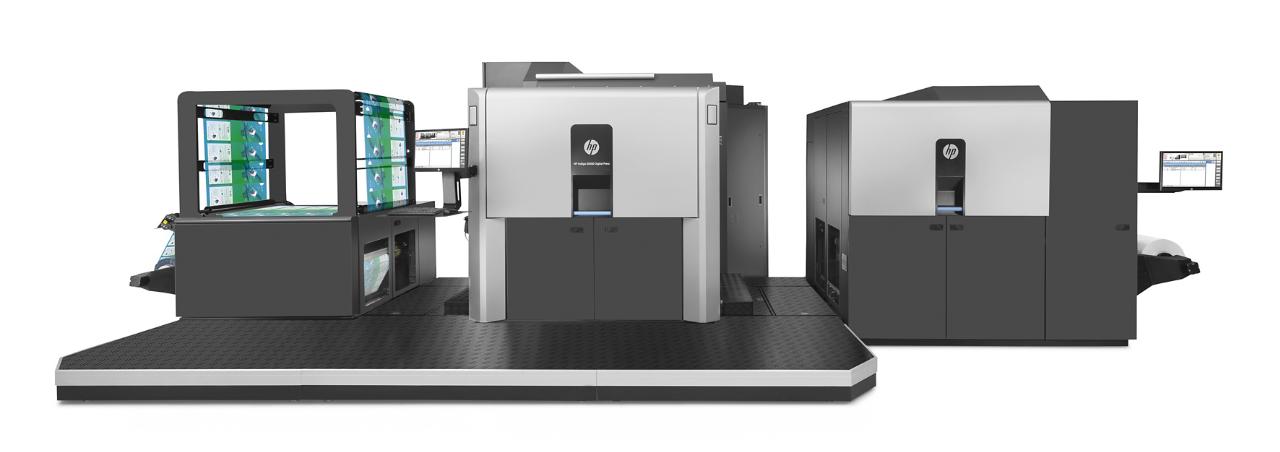

HP Indigo 20000 Expands Application Range and Features for Labels and Packaging

HP Indigo 20000:

“Digital adoption is growing, and converters need more sophisticated solutions to differentiate themselves and effectively add value to brands,” said Dave Prezzano, VP and GM, Graphics Solutions Business, Americas, HP Inc. “HP Indigo’s platform for digital labels and packaging production empowers converters to embrace the possibilities of print to create, innovate, and grow their business profitably. By optimizing supply chain and meeting sustainability goals all while helping brands engage with their consumers with state-of-the-art automated design and production management tool – HP Indigo is helping them, and their customers, thrive in a changing world.”

During the last year, the second dedicated shrink-sleeve HP Indigo 8000 was installed in the U.S. for serving the fast-growing craft beverage market.

In the last year, tens of millions of laminate tubes were printed using HP Indigo presses, including a major Korean cosmetic brand that moved production to digital for anti-counterfeiting and consumer.

HP Indigo GEM Enters First Stage of Beta Customer Testing

At Labelexpo 2017, the company announced HP Indigo GEM, the one-pass digital embellishments solution. This year, the HP Indigo GEM is in the first stage of beta customer testing and the first U.S. beta customer is Innovative Labeling Solutions.

“The HP Indigo GEM is a dramatic revolution in digital printing industry enabling us to bring a fully digital printing solution, including embellishments, to the marketplace,” said Jay Dollries, CEO, Innovative Labeling Solutions. “The cutting-edge technology delivered by HP Indigo GEM removes limitations allowing for embellishments to vary across labels further helping our business to be dynamic and responsive to deliver a broad range applications and creative capabilities.”

HP is also collaborating with LEONHARD KURZ Stiftung & Co. KG, a provider of foils, to ensure compatibility of its products with HP Indigo GEM. Additional compatible foils will be available from K Laser Technology.

HP Indigo 6900 Latest Capabilities

HP Indigo 6900:

- Pack Ready for Labels, extended to HP’s entire labels and packaging portfolio, improves the performance against water, chemical, and temperature exposure based on a new UV curable additive added to off-the-shelf varnishes, cross-linking the label ’s construction. With Pack Ready for Labels, converters can print more types of labels and eliminate costly lamination processes;

- The HP Indigo 6900 supports a wide variety of solutions including inks and software tools. The newly introduced HP Indigo ElectroInk Invisible Yellow and Blue are only visible under UV light, delivering high performance for security applications. Coupled with new software and cloud-based solutions that allow anti-counterfeiting marks, micro text fonts, and protected track and trace solutions, converters can offer unique layered security, static and serialized, for brand;

- HP Indigo ElectroInk Silver combines metallic effects with digital capabilities in one printing process, saving on metallic substrates and allowing innovation with clear media. The ink has been successfully adopted by 100+ customers and utilized for a variety of end-use markets including health and beauty, beverage, and household.

HP Indigo 20000 Expands Application Range and Features for Labels and Packaging

HP Indigo 20000:

- An extended media gamut and enhanced support of extra stretchable substrates and support of paper substrates up to 350 microns. ILP 030 primer is now available for use with the HP Indigo 20000 opening new possibilities in pressure sensitive labels;

- Premium White ElectroInk brings high opacity white printing to flexible packaging, shrink sleeves, IML and others with a thin, dry layer of ink ready for lamination and other post-print processes right off the press;

- Concentrated ink reduces oily waste from the press by up to 50% compared to previous ink supplied, as well as reduced transportation impact;

- ABGs ILC760 enables efficient and economical one-step applications production of applications including shrink sleeves, flexible packaging, IML, tubes, wrap around and more. The new ILC760 enables the top coating and slit-rewind in line with the press using industry standard water-based and UV coatings.