Metallics are one of the primary means to capture the attention of the consumer. Neil Hersh, business line manager, graphic arts for ECKART Effect Pigments, said that metallic effects continue to play an important role in the graphic arts market.

“Overall usage for metallics was fairly healthy last year, although we did see some softening towards the end of the year,” Mr. Hersh added. “The label and packaging segments are very active and have the best growth potential, while the commercial and publication segments are not as vibrant.”

Aaron Hollman, global product manager – effect pigments, Sun Chemical Performance Pigments, noted that Sun Chemical Performance Pigments has seen positive growth in metallic pigments for graphic arts during the first half of 2013.

“That being said, we are facing somewhat lower metallic pigment demand in Europe due to the economic downturn and stronger demand in the United States, Latin America and Asia,” Mr. Hollman added. “As a leading global pigment manufacturer, we are optimistic that Sun Chemical will overcome global economic challenges and see continued growth in the metallic pigments market in 2014.”

With its June 2012 acquisition of Benda-Lutz, Sun Chemical has greatly expanded its metallic effect offerings designed for inks, coatings, plastics and specialties markets.

“With the acquisition, Sun Chemical has added production facilities in Austria, Poland, Russia and the U.S. to accompany its aluminum manufacturing sites in China,” Mr. Hollman said. “Benda-Lutz has produced high quality metallic effects for more than 100 years, and we intend to utilize their experience and know-how to deliver quality, service and innovation to our customers.

Mr. Hollman said that Sun Chemical has recently introduced the Benda-Lutz brand of metallic effects for graphic arts. This line includes premium leafing grades for offset, aluminum dispersions and concentrates for flexo and gravure, stabilized aluminum powders for UV and new metallic preparations for water-based printing.

Maria Giannobile, marketing manager, pigments and colorants, Dispersions & Pigments Division, North America for BASF, aid that the market for metallics stayed fairly steady in 2012, with the best opportunities being found in packaging.

“We see the strongest growth areas for metallic in the graphic arts as UV flexo and screen,” Ms. Giannobile said. “This would translate into beverage labels, flexible packaging and narrow web labels as well as shrink sleeves.”

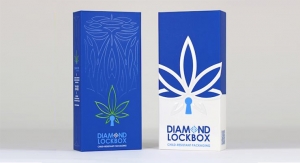

Mr. Hersh noted that brand owners are very interested in differentiating their products on the store shelves.

“Adding metallic effects to the label (pressure sensitive, wet glue, wrap around, shrink sleeves) or to the package (folding carton, flexible film, pouch) draws attention to the consumer, making their product more appealing at the point of purchase,” Mr. Hersh added. “There’s opportunity to expand the overall market for printed metallic effects, particularly as an economic and environmentally attractive alternative to foil stamping or in place of metalized substrate.”

Raw Materials

The cost and availability of raw materials have been a concern in recent years for metallics, with copper being a key challenge. Metallic pigment suppliers reported that there was some stability during the past year; for example, Ms. Giannobile said that raw material prices have not given BASF any cause for concern.

“At the moment, raw material prices have stabilized at their current high levels,” Mr. Hollman said. “However, we are certainly aware of the high degree of volatility in the global economy. Therefore, we will continue to monitor the key raw material indexes and focus our manufacturing team on process and raw material productivity.”

“During the past year there has been much better pricing stability for metallic products, and availability is less of a concern at the moment,” Mr. Hersh said. “However, there also remains more uncertainty in the global markets, so this may change given the more dynamic and volatile economic and political climate.”

Challenges for Metallics

Metallics can be challenging for printers, and metallic pigment and ink suppliers are working to create ways to ease the printers’ workload.

“Metallic inks, unlike inks manufactured from conventional organic or inorganic pigments, have a much larger particle size that need to be transferred to the substrate,” Mr. Hersh observed. “There is also the orientation of these particles that influence the desired effect. So educating the users on how to achieve the best overall effect – brilliance and coverage – will always play an important role for metallic suppliers. Working together with printers to determine the best chemistry and helping them understand and optimize the application process remains extremely important.”

ECKART Effect Pigments has introduced a number of products during the past year, including RotoStar UV FP66, a series of UV flexo inks that can be printed on paper and film, offering much longer shelf-life stability than existing UV flexo products in the market, as well as creating superior metallic brilliance with increasing press speeds. ECKART has also introduced several new products for shrink sleeves, including RotoStar UV Shrink Silver FX68-41002 for UV flexo and PlatinStar GX-2902 Silver for solvent flexo and gravure.

Due to stricter European regulations, ECKART has introduced its FPG series of low migration offset inks, manufactured under GMP guidelines in a dedicated manufacturing facility to prevent contamination and meet the most stringent migration requirements. MetalStar Supereco 10 is a cobalt- and mineral oil-free range of offset inks that has also been introduced to meet specific packaging requirements.

An NL UV offset silver that can be blended using organic inks and flushes to achieve cleaner brighter metallic colors is also coming soon, Mr. Hersh added.

Mr. Hollman said that for solvent-based applications, the key technical challenge is producing the highest quality metallic effect while balancing cost and still maintaining the functional requirements of the ink.

“Our process technologists are continuously developing finer, brighter metallic effects for our Benda-Lutz MAXAL range of premium lenticular aluminum pigments,” Mr. Hollman said. “At the same time, our applications team is optimizing the ease of use, formulation flexibility and functional requirements of the finished ink.

“For water-based and UV applications, the key technical challenge tends to be stability,” Mr. Hollman noted. “Benda-Lutz Aquaral WS is our latest stabilization technology for waterborne. By building on our well established Aquaral series, we have created a new product family with improved optical properties, stability and outstanding compatibility in a wide range of aqueous ink systems.

“We are really excited about some of the new advancements in metallized foil replacement,” Mr. Hollman added. “Our Benda-Lutz Splendal range of vacuum metallized pigments can produce outstanding mirror-like effects and are ideally suited for this application. In terms of other applications, we have a number of new products that provide unique aesthetics for packaging inks and functional effects for barrier coatings and printed electronics. These areas should continue to provide growth in the coming years.”

Ms. Giannobile noted that vacuum metalized pigments (VMPs) require expert formulation for best on press performance.

“As a supplier of VMP pigments, we have optimized surface treatments, we are looking at novel passivation chemistries and have tightened the quality control specifications in place during our production,” Ms. Giannobile said. “We aim to make the best most reproducible product possible.”

Ms. Giannobile said noted that BASF’s newest product is Metasheen UV, a VMP slurry compatible in a UV system that is scheduled for launch in Q4 2013.

Expectations for the Coming Year

Metallic pigment manufacturers say they anticipate that the market for metallics will continue to grow in the coming year.

“With expectations of growth in the packaging market and the impact of metallic effects in packaging, we expect there will be market growth in 2013,” Ms. Giannobile said.

“This year has started out a little soft for metallics but product inquiries and project activity remain very encouraging,” Mr. Hersh said. “The market should improve as these requests and opportunities begin to commercialize.”