David Savastano, Ink World Editor01.20.11

When there is a lengthy economic downturn, capital improvement budgets are often one of the areas that are cut. As a result, milling and mixing equipment manufacturers have felt the impact of the global recession.

With the worst of the recession apparently over, ink companies are starting to move forward on their equipment needs.

Rene Eisenring, GD sales manager, Buhler Inc. USA, said that Buhler has seen quite a turnaround in 2010 over 2009.

“I personally believe that the biggest change was that many companies are trying very hard now to lower the operating cost with better equipment and with equipment that is using less energy, but still gets the job done,” Mr. Eisenring noted.

“In 2010 as in past years, ink companies continued to try and improve their inks and dispersions through product development, and in this area we have been able to provide laboratory research bead mills and dispersers to help develop these new products,” said Dave Peterson, president of EMI – Eiger Machinery, Inc. and CDC Microtron USA, Inc. “Purchases that were held up because of the previous year’s economy may have come through in 2010.”

“We experienced a major improvement in both inquiries and new equipment orders specifically for our high viscosity immersion mill,” said George Murphy, vice president sales and marketing, Hockmeyer Equipment Corp.

“Myers experienced a heavy increase in requests for design assistance and quotations in the last quarter of the year,” said Cathy Strahan,marketing director, Myers Engineering, Inc.

Brian Li, region business director for Union Process, said it seemed like there was some improvement in the ink industry this year.

“We have experienced a relatively flat market in terms of overall sales. However, the activity level in the industry over the past six months would indicate it’s poised for substantial growth in 2011 and beyond,” Mr. Li added.

Growth Markets

Milling and mixing equipment manufacturers have seen growing interest in a few select fields, notably on the digital side as well as nanotechnology For example, Rosanna DeLuca, sales associate at Jaygo Inc., noted that there is strong interest in manufacturing inkjet and barcode inks.

“We have seen the most business and growth in theelectronic market and in the renewable energy market, like solar materials,” Mr. Eisenring said. “As for the ink market, I would say that metal deco and digital ink had a good year in 2010.”

“We have seen a great increase in inquiries about both our high viscosity immersion mill and our nano mill for inkjet applications,” Mr. Murphy said. “Companies are extremely interested in learning more about our patented technologies and how they can substantial improve their manufacturing and reduce their overall costs.”

“The areas of most interest seem to be in nanotechnology, and how these finer submicron particles benefit ink dispersions and in particular digital inks,” Mr. Peterson said.

“In a niche market, we have noticed an increase in interest for screening inks as well as applications for printing on silicon rubber type materials,” said Mr. Li.

Ink Industry Requirements

Ink manufacturers are looking for a variety of characteristics from their new equipment, beginning with greater efficiency and lower energy consumption. For example, Ms. DeLuca pointed to the interest in safety and efficiency. Mr. Eisenring said that customers are prioritizing high performance with lower energy use, as well as high quality mill parts for longer operation with less downtime and best service available.

Mr. Li said that it seems like companies are looking for a narrow particle size distribution, which means a more uniform product, and the milling equipment must be able to consistently produce this fine uniform grind.

Mr. Peterson said that ink companies are looking for machine flexibility, reliability, ease of use, faster processing rates and the ability of the equipment to produce higher quality inks and dispersions.

“We’ve really seen a continuation of the need for reducing particle size and improving dispersions in the least amount of time,” Ms. Strahan added.

“On the milling front, we have seen two major areas of concern by ink manufacturers,” Mr. Murphy said. “One is eliminating the steps required to manufacture products, and the second is addressing issues with inkjet manufacturing equipment reliability.”

Service is a key differentiator for mill and mixer customers.

“Service, spare parts and serviceability of the equipment is the key factor today to differentiate equipment suppliers,” Mr. Eisenring noted.

“Service is always of utmost importance, but what’s often hard to decipher is ‘Quality,’” Mr. Li said. “Like most products, there are cheap versions, and also very expensive versions, the key is finding a company that not only has good service, but offers ‘Quality’ that you can trust, time and time again.”

“While we pride ourselves on our service, what we have seen is that ink manufacturers are concerned about the level of service required by some mills,” Mr. Murphy said. “We have also seen increased interest in eliminating roll mills by using our HCP-S high viscosity mill that can consolidate ink processing in one machine thereby eliminating the amount of maintenance required.”

“In many cases, customers like the idea of being able to process a dispersion sample in our Grayslake, IL laboratory where we can review their standard and compare it to what our equipment will do,” Mr. Peterson said. “We will even process small dispersion batches for customers which they can submit to their customer to see if it makes sense for them to add equipment to make new products at their own plants. Knowledgeable and available technical support staff is always important to customers.”

Newest Technologies

In order to meet the needs of ink manufacturers, leading mill and mixer manufacturers have developed new technologies.

For example, Myers Engineering has designed a mini lab mixer that helps reduce waste in the very early stages of formulating, while the DMQ SeriesAttritor from Union Process has the capacity to produce fine particle sizes down to the sub-micron range with easier maintenance than traditional models.

Buhler has introduced a full volume bead mill to the market.

“After the last introduction by Buhler of the MicroMedia bead mill for very fine beads and nano applications, we now introduce the new full volume bead mill with higher economics,” Mr. Eisenring said. “The mill series comes in many sizes, from 30 to 1200 liters (8 to 315 gal.) and is called Centex. This new and superior full volume bead mill will give our customers a much higher productivity with the use of a smaller process chamber. Buhler has optimized the process chamber and added the new SCS (Superior Centrifugal Separation) media separator system. The mill will produce higher flow rates with the new EcoMizer discs for efficient acceleration of the grinding beads, with reduced rotor speed, resulting in more economical grinding.”

Jaygo is showcasing its Altern Mill, a single processor for ultra-fine grinding operations.

“It combines the features of a disperser and a mill, such as less product loss, less contamination and less exposure,” Ms. DeLuca noted. “It is an environmentally safe, clean, closed system that offers reproducible high quality dispersions.”

Nanotechnologies are an area of much interest, and CDC Microtron USA and Hockmeyer Equipment have designed new products for the market.

“The new Nanotron mill from CDC Microtron USA, Inc. will allow ink and dispersion companies to produce nano pigment dispersions like inkjet with improved quality and at faster production rates. Cost and flexibility of the Nanotron is a key benefit,” Mr. Peterson said. “The EMI Mini mills help in the research of these nano dispersions by being able to process inks with media as small as 0.1 mm diameter, which can open up new opportunities in ink and pigment grinding.”

“Our most recent product introduction was the patented HCP-N nano mill for use with 0.1 to 0.3mm media,” Mr. Murphy said. “Our HCP-N mill is not only substantially faster than other products in the market, but it also eliminates issues with mill breakdowns due to the use of very small media.”

For more information on the milling and mixing markets, including new products and the importance of customer service, please see the online version at www.inkworldmagazine.com.

With the worst of the recession apparently over, ink companies are starting to move forward on their equipment needs.

Rene Eisenring, GD sales manager, Buhler Inc. USA, said that Buhler has seen quite a turnaround in 2010 over 2009.

“I personally believe that the biggest change was that many companies are trying very hard now to lower the operating cost with better equipment and with equipment that is using less energy, but still gets the job done,” Mr. Eisenring noted.

“In 2010 as in past years, ink companies continued to try and improve their inks and dispersions through product development, and in this area we have been able to provide laboratory research bead mills and dispersers to help develop these new products,” said Dave Peterson, president of EMI – Eiger Machinery, Inc. and CDC Microtron USA, Inc. “Purchases that were held up because of the previous year’s economy may have come through in 2010.”

“We experienced a major improvement in both inquiries and new equipment orders specifically for our high viscosity immersion mill,” said George Murphy, vice president sales and marketing, Hockmeyer Equipment Corp.

“Myers experienced a heavy increase in requests for design assistance and quotations in the last quarter of the year,” said Cathy Strahan,marketing director, Myers Engineering, Inc.

Brian Li, region business director for Union Process, said it seemed like there was some improvement in the ink industry this year.

“We have experienced a relatively flat market in terms of overall sales. However, the activity level in the industry over the past six months would indicate it’s poised for substantial growth in 2011 and beyond,” Mr. Li added.

Growth Markets

Milling and mixing equipment manufacturers have seen growing interest in a few select fields, notably on the digital side as well as nanotechnology For example, Rosanna DeLuca, sales associate at Jaygo Inc., noted that there is strong interest in manufacturing inkjet and barcode inks.

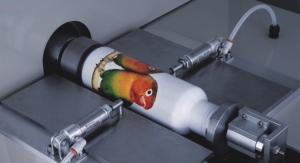

“We have seen the most business and growth in theelectronic market and in the renewable energy market, like solar materials,” Mr. Eisenring said. “As for the ink market, I would say that metal deco and digital ink had a good year in 2010.”

“We have seen a great increase in inquiries about both our high viscosity immersion mill and our nano mill for inkjet applications,” Mr. Murphy said. “Companies are extremely interested in learning more about our patented technologies and how they can substantial improve their manufacturing and reduce their overall costs.”

“The areas of most interest seem to be in nanotechnology, and how these finer submicron particles benefit ink dispersions and in particular digital inks,” Mr. Peterson said.

“In a niche market, we have noticed an increase in interest for screening inks as well as applications for printing on silicon rubber type materials,” said Mr. Li.

Ink Industry Requirements

Ink manufacturers are looking for a variety of characteristics from their new equipment, beginning with greater efficiency and lower energy consumption. For example, Ms. DeLuca pointed to the interest in safety and efficiency. Mr. Eisenring said that customers are prioritizing high performance with lower energy use, as well as high quality mill parts for longer operation with less downtime and best service available.

Mr. Li said that it seems like companies are looking for a narrow particle size distribution, which means a more uniform product, and the milling equipment must be able to consistently produce this fine uniform grind.

Mr. Peterson said that ink companies are looking for machine flexibility, reliability, ease of use, faster processing rates and the ability of the equipment to produce higher quality inks and dispersions.

“We’ve really seen a continuation of the need for reducing particle size and improving dispersions in the least amount of time,” Ms. Strahan added.

“On the milling front, we have seen two major areas of concern by ink manufacturers,” Mr. Murphy said. “One is eliminating the steps required to manufacture products, and the second is addressing issues with inkjet manufacturing equipment reliability.”

Service is a key differentiator for mill and mixer customers.

“Service, spare parts and serviceability of the equipment is the key factor today to differentiate equipment suppliers,” Mr. Eisenring noted.

“Service is always of utmost importance, but what’s often hard to decipher is ‘Quality,’” Mr. Li said. “Like most products, there are cheap versions, and also very expensive versions, the key is finding a company that not only has good service, but offers ‘Quality’ that you can trust, time and time again.”

“While we pride ourselves on our service, what we have seen is that ink manufacturers are concerned about the level of service required by some mills,” Mr. Murphy said. “We have also seen increased interest in eliminating roll mills by using our HCP-S high viscosity mill that can consolidate ink processing in one machine thereby eliminating the amount of maintenance required.”

“In many cases, customers like the idea of being able to process a dispersion sample in our Grayslake, IL laboratory where we can review their standard and compare it to what our equipment will do,” Mr. Peterson said. “We will even process small dispersion batches for customers which they can submit to their customer to see if it makes sense for them to add equipment to make new products at their own plants. Knowledgeable and available technical support staff is always important to customers.”

Newest Technologies

In order to meet the needs of ink manufacturers, leading mill and mixer manufacturers have developed new technologies.

For example, Myers Engineering has designed a mini lab mixer that helps reduce waste in the very early stages of formulating, while the DMQ SeriesAttritor from Union Process has the capacity to produce fine particle sizes down to the sub-micron range with easier maintenance than traditional models.

Buhler has introduced a full volume bead mill to the market.

“After the last introduction by Buhler of the MicroMedia bead mill for very fine beads and nano applications, we now introduce the new full volume bead mill with higher economics,” Mr. Eisenring said. “The mill series comes in many sizes, from 30 to 1200 liters (8 to 315 gal.) and is called Centex. This new and superior full volume bead mill will give our customers a much higher productivity with the use of a smaller process chamber. Buhler has optimized the process chamber and added the new SCS (Superior Centrifugal Separation) media separator system. The mill will produce higher flow rates with the new EcoMizer discs for efficient acceleration of the grinding beads, with reduced rotor speed, resulting in more economical grinding.”

Jaygo is showcasing its Altern Mill, a single processor for ultra-fine grinding operations.

“It combines the features of a disperser and a mill, such as less product loss, less contamination and less exposure,” Ms. DeLuca noted. “It is an environmentally safe, clean, closed system that offers reproducible high quality dispersions.”

Nanotechnologies are an area of much interest, and CDC Microtron USA and Hockmeyer Equipment have designed new products for the market.

“The new Nanotron mill from CDC Microtron USA, Inc. will allow ink and dispersion companies to produce nano pigment dispersions like inkjet with improved quality and at faster production rates. Cost and flexibility of the Nanotron is a key benefit,” Mr. Peterson said. “The EMI Mini mills help in the research of these nano dispersions by being able to process inks with media as small as 0.1 mm diameter, which can open up new opportunities in ink and pigment grinding.”

“Our most recent product introduction was the patented HCP-N nano mill for use with 0.1 to 0.3mm media,” Mr. Murphy said. “Our HCP-N mill is not only substantially faster than other products in the market, but it also eliminates issues with mill breakdowns due to the use of very small media.”

For more information on the milling and mixing markets, including new products and the importance of customer service, please see the online version at www.inkworldmagazine.com.