Dr. Pinaki Ranjan Samanta*, Dr Manisha, Mr. Kaushal Kishor Choudhary, Ms. Kahkashan Bano and Mr. Prem Kumar Nautiyal10.04.23

Abstract

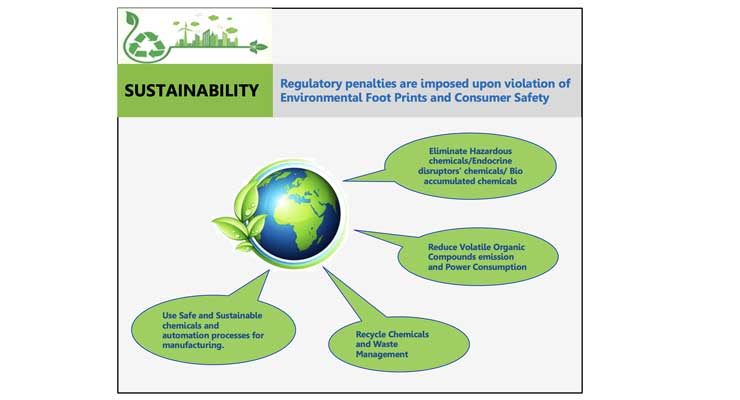

Sustainability initiatives are being adopted across industries due to strict government regulations, coupled with increasing consumer awareness regarding environmental degradation. The coating industries, like printing ink and adhesives, which accounts for a high share of air pollution, is also adopting sustainability measures in its various functions, including manufacturing and procurement.Today, sustainability aspects are routinely considered when performing most business operations, often on a daily basis. The focus has expanded well beyond reducing volatile organic compounds (VOCs) to include energy and resource conservation, waste minimization, process efficiency enhancement, use of renewable materials, and much more.

The goal is to develop sustainable products and solutions, reduce the carbon footprint of our own operations, and support our customers to meet new regulations and achieve their sustainability goals.

The approach is to minimize the environmental impact across the value chain, from sourcing raw materials and manufacturing to distribution, reuse, and recycling. Document the environmental impact of products by using the Life Cycle Analysis as the main tool, along with other sustainability assessment approaches.

The efforts to reach the goals involve everyone – the manufacturer, strong partners and devoted customers. Only together can we create a truly sustainable and circular economy.

Business plays a crucial role in creating a sustainable society. Three elements define sustainable thinking: health, climate change, and circularity. They translate into the following sustainability drivers for printing ink and adhesive industries – elimination of toxic ingredients, reduction of VOCs to improve and protect indoor and outdoor air quality, reduction of carbon footprint, and an increased use of bio-based ingredients.

This article focuses on sustainability, green policy on chemical industries, measurement criteria and regulation obligations on printing inks, adhesives and coatings etc.

Introduction

Sustainability and the environment have been at the forefront of the public consciousness in recent years, with the effect of climate change and other factors sparking increased consciousness in public and private sectors. It’s one of the reasons why “green,” “sustainability,” and “ecofriendly” ideas have become prominent for business leaders and manufacturers.The growing market for eco-friendly inks checks out some of the industry’s most innovative ways to improve ink’s environmental credentials, from biodegradable and soy-derived inks to water-based techniques. The use of eco-friendly inks and printing techniques is on the rise as the packaging world continues its drive to reduce its environmental impact.

National and international governments are now adopting environmental regulations which specifically address the content of ink, like the European Union’s EN 134323 standard on packaging compostability

Inks can be any color these days as long as they are “green.” Without a doubt, sustainability has become a major issue in packaging converting, and much of the focus has been on substrates. We’ve all seen stories that it’s the substrate that takes up a lot of room in those landfills. If it isn’t easily biodegradable, then it better be recyclable.

Many people feel that inks are the next big issue in sustainable packaging. Even though inks constitute such a small part of the package, their impact is huge. After all, inks provide the product’s marketing message. Ink makers and printers need to take note that printing end users are starting to demand that their packaging be printed with inks that contribute to the package’s sustainability. Of course, these inks are expected to perform equally as well at an economical price.

When it comes to packaging, inks and substrates are married to each other. Once the two materials are bound, they are difficult to separate. But it does happen in recycling and in disposal, and the results can contribute to worsening

environmental conditions.

Due to increased government regulation, public pressure and a desire to make production practices more efficient, the manufacturing community has been on the forefront of creating a new, sustainable green world. The printing industry is

no exception.[1-5]

What is Sustainability?

Sustainability is the capacity to endure long maintenance of well-being. It has three pillars: Social, Environmental, and Economical. It should be measured. Detailed Standards and Certifications should be established.Sustainability is the key driver behind the current transformation to circular and bio economy towards United Nations Sustainable Development Goals. The urgency of climate change is motivating individuals, companies and their customers to move towards sustainable lifestyles, products and production. All leading-edge companies today share the pain and want to do the right thing – but what are the best strategies and choices, and their impacts? Will we meet the new customer demand and be compliant with future targets and regulations? How do we credibly communicate our sustainability benefits to our key customers?

A well-designed sustainability strategy, based on fact-based reasoning, provides a sound and future-looking foundation for making business. We also need improved processes, technologies and eco design practices to strive in the market. Understanding sustainability factors early on in the R&D cycle will help de-risk the development project:

• Communicating efficiently to customers

• Basing sustainability strategies on facts and science

• Comparing alternative raw materials, technologies and business solutions

• Designing R&D initiatives to support sustainability targets

• Ensuring and planning for compliance with futureregulations

• Supporting government policies on decision-making

Conservation, Community, and Corporate Culture

Conservation – To create quality products with minimal environmental impact and committed to using renewable and natural-based raw materials to achieve this. Sourcing raw materials from sustainably-managed operations and aim to quantify the environmental impact of raw materials and end products. To design formulation of inks for easy use by customers to increase efficiency, which results in using the least amount of ink necessary.Community – To support communities where everyone can live life to the fullest. For maximum benefit to society, industry must conduct business proposals with awareness of its impact on communities. Take the interests of employees, their families, and the communities where they work with great concern. Must believe in fostering strong relationships with their customers and the surrounding communities while supporting efforts to create a circular economy.

Corporate culture - Corporate culture reflects the commitment to manufacturing and delivering products using the least resources. Also state-of-art production equipment promotes a manufacturing culture that produces the least carbon emissions.

An Eco-Friendly Approach to Sustaining Our Planet

To introduce eco-friendly strategies to achieving a circular economy involves a Life Cycle Assessment (LCA). Life Cycle Assessment (LCA) aims to quantify the environmental impacts that arise from material inputs and outputs, such as energy use or air emissions, over a product’s entire life cycle to assist consumers in making decisions that will benefit the environment.Cradle-to-gate approach is most commonly used for the life cycle assessment of a paint product. It takes into account all life cycle stages, from raw material extraction up to the distribution of the final product.

The system that evaluates the environmental impact of their products and raw materials throughout their life to determine the optimum ink products for reducing the environmental impact, such as carbon emissions.

Other sustainable practices must include:

• Materials selection – Sourcing of raw materials from sustainably managed resources

• Manufacturing – Always aim to use production methods with efficient energy usage and zero waste production

• Transportation – To identify higher-efficiency transportation and downsize packages to minimize carbon emissions

• Using products – All product development goals include reducing harmful environmental impact

• Waste disposal – To be introduced refillable and replaceable packaging to minimize waste

• Promoting sustainability – To work with consumers and surrounding community

What is ‘Green’ Policy?

(A) Source ‘green’ materials. (B) Source materials which do not contain toxic, hazardous or suspect raw materials. (C) Reduce energy use and CO2 emissions. Target being carbon neutral. (D) Minimize environmental impact by:• Waste reduction

• Improved recyclability

• Improved biodegradability

• No toxic waste, even more no toxics when waste is incinerated

• Reduce CO2 emissions.

• Ecofriendly products and Green Credit Points of Inks and Adhesive distribution available online of our paper

Eco Friendly products and Green credit points of Printing Inks and adhesives distributed as per following tables: (see full table online in our website www.inkworldmagazine.com)

Sustainable Inks and Adhesives Guidance for Raw Materials Selections

Petroleum is a non-renewable resource, while the plants used for vegetable-based ink are fast growing and renewable. Oil-producing plants can be widely cultivated and oils can be easily extracted and refined. In addition, VOC-free inks eliminate the release of greenhouse gases. Finally, vegetable-based inks are easier to remove during recycling’s deinking process than petroleum-based inks.Requirement for Sustainability Inks and Adhesives

• Elimination of toxic/hazardous raw materials in the inks.• Non-toxic waste.

• Biodegradability and recycling/de-inking : improved due to chemistry and no toxic materials.

• Work towards zero volatile organic compounds (VOC).

• Improved biodegradability of binders/resins and waste.

• Improved compostability of binders/resins and waste.

• Reduced CO2 emissions waste reduction of binders and resins.

• No dioxin during burning waste.

• Halogen-free pigments.

• Nano particles not favored for pigments.

• Avoid natural pigments which contain toxic materials.

• Avoid banned items like phenol-based resins (BPA/PF), tin catalyst.

• Use bio solvents (mostly used esters of fatty acids, derived from vegetable oils. Example: FAME, which is fatty acid methyl ester).

• GMO-free and not based on animal fat: preferable.

• Additives from bio raw materials.

• Bio Renewable Content (BRC) should be more than 60%.

• Ecologically friendly.

Obligations Towards Compliances

Owing to the vast size of the chemical industry, wide array of chemistries and product categories, dependence of various customer industries on chemicals, number of direct and indirect employees and their safety and livelihood, it is essential for the industry to have a robust regulatory mechanism in place.Therefore, several regulatory mechanisms of varying stringencies are implemented by the chemical sectors of different countries globally, at national and regional levels. National and regional compliances are implemented in the form of standards, rules and legislations to enable chemical management.

These include targeting the complete lifecycle of chemicals – beginning with their manufacturing process, until they are disposed or recycled. Chemicals are used by various stakeholders across different sectors during their lifecycle.

As a result, chemical companies are compliant with all the cross-sectoral legislations and regulatory frameworks, which are implemented by authorities using various legal instruments and methods. Product registration, its labeling and classification, technical and safety data sheet of product, product-quality inspections, permissions for sale, applicability of licenses to operate the chemical plants and discharge waste, waste discharge limits, etc., are some of the legal instruments and ways by which chemical companies are bound. Thus, chemical companies must comply with the laws and legislations for:

• Chemical management and handling

• Chemical usage

• Environmental management

• Chemical disaster and emergency management

• Special categories of chemicals.

Some large chemical companies and chemical industry associations have gone past the mandatory regulations set forth by the government and are setting more standards for the management of chemicals and adoption of clean technologies.

While the voluntary measures introduced by industry associations are proactively taken up by larger players, smaller organizations often struggle to go further than the mandatory compliances and are unable to take up voluntary measures. This is primarily because of the limited manpower and availability of resources.

While the focus of chemical companies has always been to comply with the regulations, they struggle with unanticipated events such as accidents resulting in release or spillage of chemicals, insufficient control mechanisms leading to pollution, gaps in coordination between government and regulatory agencies, outdated technologies to comply with and support increasingly stringent regulations and unavailability of a trained workforce.

How can the printing inks and adhesive industries enable sustainable solution?

The last two decades have seen global sustainability trends gather increasing momentum due to climate change, resource scarcity and development of digital technologies. These trends have also influenced customer buying behavior.Climate change and resource scarcity have led to increased raw material price volatility and tighter environmental regulations. Further, advancements in digital technologies have enabled the development of affordable tracking tools/mechanisms and communication systems, which have now become the norm.

Customers are increasingly demanding environment-friendly and socially responsible products which do not add to their carbon footprint. At the same time, they expect organizations to improve the overall performance and efficiency of their manufacturing setups. The chemical industry is quite well positioned to respond to such trends and address sustainability issues pertaining to its own footprint.

As a key intermediary, the chemical industry can influence sustainability and innovation across its value chain to respond to both regulatory and customer requirements. With its products, customer industries can drive innovation in their manufacturing processes and products. It’s important to focus on the following points:

• Digital technologies.

• Creating cradle to gate (farm to fork) data transparency.

• Reducing waste and enabling circularities.

• Nudging consumer behavior I sustainability.

• Paradigm shifts and out of box thinking.

Biodegradable Plastics Challenges

Biodegradable plastics may bring degradation and toxicity challenges. The European Commission (EC) has also reported on biodegradable plastics in the open environment and concluded that these materials are no silver bullet for inappropriate waste management or plastic littering. Biodegradation tests performed in the laboratory would not reflect natural environments, e.g., microbial composition, or available carbon source. This would mean that if harmful compounds are released during biodegradation it would not necessarily be detected.Normally, biodegradable plastics are designed for microbial conversion into CO2, methane, biomass, and mineral salts. Universal biodegradability in any ecosystem on earth does not exist since the parameters determining biodegradation rates (water, nutrients, temperature, etc.) vary great extent.

Conclusion

Changing the way of interacting with packaging, printing ink and adhesives manufacturer requires us to rethink the way they produce and consume. We need to ensure that the changes made to packaging and delivery system work for the communities that enjoy products around the world every day. It is about exploring multiple solutions and it requires collaboration and innovation on a global scale. By working with global leaders, we want to create a lasting and impactful change, a change for the better for people and the planet.Sustainable packaging and printing ink is no longer focused on just recycling it involves increased use of life cycle inventory and life cycle assessment to help guide the use of packaging and inks, reducing the environmental impact and ecological foot print. The goals are to improve the long-term viability and quality of life for humans and the longevity of natural ecosystems. Sustainable inks must meet the functional and economics need of the present without compromising the ability of future generations to meet their own needs. It is not necessarily at the end state but is a continuing process of improvement.

Acknowledgement

The authors are overwhelmed in all humbleness and gratefulness to acknowledge for writing this article to Uflex management, who helped to put these ideas well above the level of simplicity and something concrete. It is a genuine pleasure to express our deep sense of thanks and gratitude to our colleagues for their timely advice, meticulous scrutiny, scholastic advice and scientific approach to a very great extent.Authors: Dr. Pinaki Ranjan Samanta has more than 29 years of experience in the areas associated to Industrial research of coating chemistry and testing of finish products and raw materials of coating-related products. He received M. SC and Ph. D in the field of organic chemistry, also done PG diploma in paint technology.

Dr. Manisha, masters in chemistry from IIT, Roorkee and Ph.D in chemistry with more than 12 years of experience is currently with Uflex Limited, Noida as manager (R&D), and prior to this, worked as Sr. Scientist with Jubilant Agri and consumers products Ltd.

Mr. Kaushal Kishor Chaudhary, M.Sc in chemistry from IEC University. He has an analytical scientist and worked with Arbro Pharmaceuticals Ltd, Jubilant Generics Ltd. He comes with an overall work experience of nine years.

Ms. Kahkashan Bano, masters in chemistry, is currently working with Uflex Limited, Noida as chemist (R&D- Regulatory Affairs). She has three years’ experience and expertise in the area of analysis by using state-of-the-art instruments like HPLC, GC, FTIR, UV-spectrophotometer and wet chemistry.

Mr. Prem Kumar Nautiyal, a post graduate and M. Phil in chemistry along with Certified Black Belt and PGDMM with 34 years of industrial experience in various industries and he is hardcore synthetic chemist with specialty in design &development of polyurethane laminating adhesive. Currently he is working with Uflex Limited (Chemical Division) as HOD – R&D - Accountable for development of new formulations, new products.

Reference

1. Printing ink, polymers and food packaging – Insight into the unique challenge and vulnerability towards compliance of materials and global regulatory issues - Part 1 and Part 2; by Dr. Pinaki Ranjan Samanta, Dr. Ruchi Gupta, Ms. Ritu Gupta, Ms. Shweta Chauhan and Mr. Anuj Johri ; April –May 2020: www.polymers paint color journal.com/issues or www.coatingsgroup.com.2. Articles from Packaginglaw.com; a resource provide by Kehller and Heckman LLP.

3. Regulation (EC) No 1935 / 2004 of the European Parliament and of the council of 24 Oct, 2004.

4. Presentation of Sustainability of Printing Inks in Packaging by Jack Baarends (Green 4 Print-June 2013).

5. Tetra Pak research study Consumer Environmental Trend Report – Sustainable Packages- October 2019 www.tetrapack.com.

Disclaimer: The views expressed are solely the corresponding author’s personal opinion. Uflex Ltd will not accept any liability for any loss or damage that may occur from the use of this information nor do we offer a warranty against patent infringement.

* Corresponding Author (Email: pinaki.chem@uflexltd.com)

**www.uflexltd.com