Dr. Pinaki Ranjan Samanta*, Dr. Manisha, Ms. Ritu Gupta, Ms. Shweta Chauhan and Mr. Prem Kumar Nautiyal, Regulatory Affairs and Analytical Department Uflex Ltd** (Chemical Division), C-5-8, Sector-57, Noida, Uttar Pradesh, India10.13.21

Part 1

Expressions of concern about impurities in food contact materials have increased over the last few years. Chemical compounds that are incorporated within polymeric materials to improve functionality, may interact with food components during processing or storage and migrate into the food. Food contact materials (FCM) may contain intentionally added substance (IAS) and non-intentionally added substance (NIAS) which comes from reaction by-products, breakdown or degradation products; impurities from raw materials used their production, chemical reaction between packaging materials and foodstuff, side products or neoformed compounds and contaminants picked up during the production and recycling process.

Chemical migration of intentionally added substance (IAS), non-intentionally added substance (NIAS), and not listed substance (NLS) from food packaging is affected by a number of parameters including the nature and complexity of foods, contact time and temperature of the system, type of packaging contact layer, and properties of IAS , NIAS and NLS.

New packaging development requires a safety evaluation which helps to mitigate potential health risks, which always implicate the application of complex analytical methods. This article provides a comprehensive overview of migration theory and analytical approach towards identification of migrated IAS, NIAS, and NLS by different analytical strategies.

Keywords: NIAS, IAS, Food Packaging, Migration, Impurities.

* Corresponding author (Email: pinaki.chem@uflexltd.com)

** www.uflexltd.com

Packaging encompasses a wide range of material types across plastics, glass, metal, and paper. Due to their chemical structure and properties, the most applied materials in the food industry are plastics. In addition to traditional petroleum-based polymers, biodegradable plastics and biopolymers can also be found today on the market. It should be highlighted that food contact materials (FCM) can be very complex structures created with the application of adhesives. Multi layers can not only be composed of polymers but also paper and/or aluminum that are often coated by adhesives and printing inks.

Modern society requires modern solutions, especially in the area of food safety and thus food packaging.

Food contact materials (FCM) include all materials and articles intended to come into contact with food. The FCM is produced from raw materials and so-called intentionally added substances (IAS) which increase shelf-life but also enhance the manufacturing, stability, and mechanical properties of the FCM itself.

IAS includes organic pigments, oligomers, low molecular weight resins, monomers, prepolymers, antioxidants, lubricants, surfactants, photoinitiators, and UV stabilizers. In addition to IAS, FCMs may also contain non-intentionally added substances (NIAS) which originate from reaction by-products, oligomers, degradation processes, chemical reactions between the packaging materials and the foodstuff, or as impurities from the raw materials used for their production. FCM of flexible packaging incorporated with chemical compounds is commonly referred to as plastics. Incorporation of low-molecular-weight chemical compounds improves the functional properties of plastics. However, the potential influence of these substances on product safety and quality remain in question when the amount of these migrating compounds in food exceed their specified limits. The term “migration” refers to the diffusion of substances from a zone of higher concentration (the food-contact layer) to one of a lower concentration (usually the food surface). This process is often influenced by food-packaging interactions (Arvatoyannis and Bosnea 2004) and the temperature of the system.

The phenomenon of IAS and NIAS is not new, but has raised awareness since they were specifically mentioned in Article 19 of Regulation EU 10/2011 (European Commission, 2011). This Regulation states that: “NIAS are permitted in final plastic articles but should be assessed by the manufacturer in accordance with internationally recognized scientific principles on risk assessment.” On January 28, 2016, the European Food Safety Authority (EFSA) Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids concluded that the required toxicity data for substances in FCM’s (IAS and NIAS) should be related to the expected human exposure and proposed three threshold levels of human exposure as triggers for requiring additional toxicity data: 1.5, 30 and 80 μg/kg body weight/day (EFSA, 2016). However, often a quantitative analysis of NIAS is not possible since reference standards are not available [1-7].

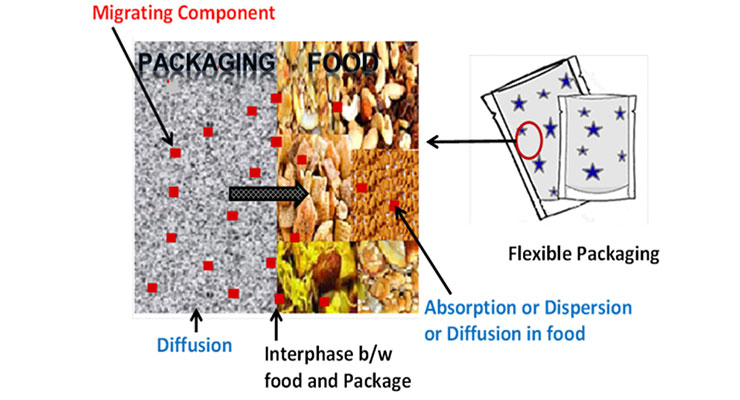

• Diffusion of migrant in package wall toward package/food interface. Frequently this is the slowest or rate-determining step of migration. In a dual interactive mode, concurrent penetration of solvent or food ingredient may change the package wall structure to a swollen state increasing the mobility of migrants.

• Dissolution of migrants at package/food interface. The dissolution depends on the affinity of migrants to the package phase and food phase.

• Dispersion or diffusion of migrants into food. The migrant will then disperse into liquid foods or diffuse into solid foods.

Schematic Diagram of Migration Mechanism as follows:

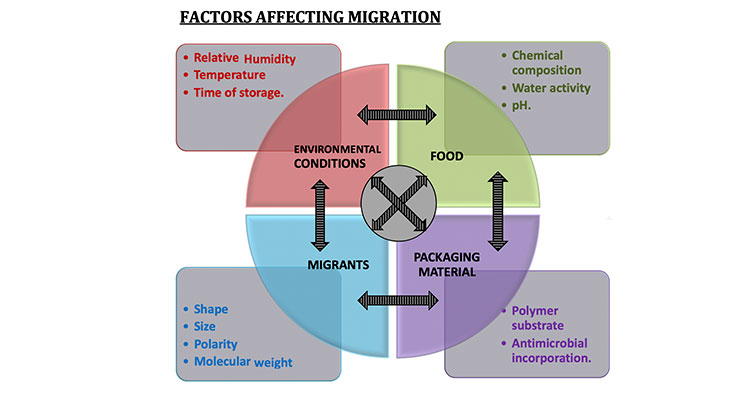

• Temperature

• Time

• Nature/Composition of Food

• Nature/Structure of packaging

• Amount of Migratable substance in Packaging.

• Ratio between packaging surface area and volume / Weight of packaged food.

FACTORS AFFECTING MIGRATION us

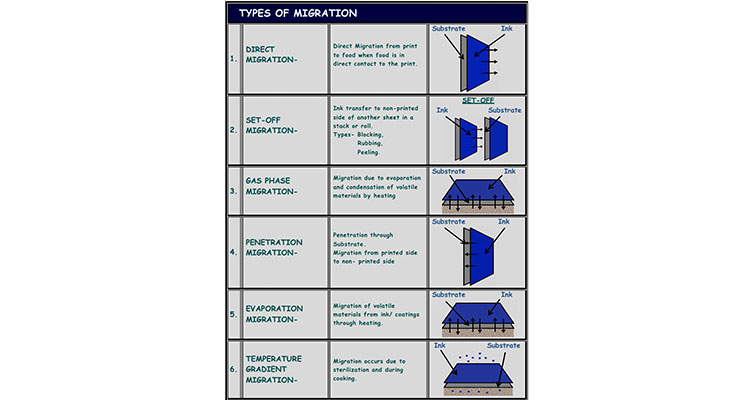

Set-Off - The transfer of un-polymerized ingredients from the print surface to the food contact surface. Examples are labels that are rolled up on them, or cylindrical containers that are stacked with the outer printed surface of one container coming in contact with the inner surface of the next in the stack.

Vapor Phase - Ink compounds and substrates that are volatilized through heating, allowing compounds to permeate through the packaging. An example would be a microwave meal that you leave the printed top on when cooking.

Condensation Extraction - Condensation of ink compounds during cooking or factory sterilization through steam distillation.

• Positive lists or inventory lists of all the known ingredients need to make the food contact materials – monomer, additives, processing aids, solvents etc.

NIAS – Not Intentionally Added Substance

• Isomers and impurities of known ingredients.

• Reaction Products and Breakdown Products of these ingredients (formed during thermal polymerizations, thermal processing, action of heat, light on the FCM).

• Other impurities especially those coming from recycling.

IAS, NIAS and NLS are always present in Food Contact Materials and they can potentially migrate into foods. They migrate due to heterogeneous medium with free volume and thermal motion of chain segments. It may free, not covalently bonded, molecular mass lower than 1000 Dalton, Chemically nature different from medium, Dimensions with respect

to medium.

or aging.

An example of neo-formed NIAS are Poly Aromatic Amines (PAAs) in polyurethane (PU) adhesives. PU adhesives are formed by the polymerization of polyols and diisocyanate monomers. If the adhesive has not been properly cured or if the ingredients have not been properly mixed, the polymerization reaction is not efficient enough and the remaining non-polymerized aromatic isocyanates can produce PAAs in contact with moisture. In addition to PAAs, other NIAS may be formed from laminatingadhesives Epoxy-based oligomers may contain bisphenol A (BPA) and bisphenol A diglycidyl ether (BADGE).

To be continued...

great extent.

Dr. Manisha, Masters in chemistry from IIT and Ph.D in chemistry with more than 9 years of experience in the field of Analytical and Polymer Analysis is currently with Uflex Limited, Noida as manager (R&D).

Ms. Ritu Gupta, Masters in Chemistry, is currently working with Uflex Limited, Noida as chemist (R&D instrumentation). She has research experience of more than two years with the expertise in the area of analysis by using state-of-the-art instruments like Py- GC-MS, GC-HS, FTIR, UV-spectrophotometer etc.

Ms. Shweta Chauhan is an engineering graduate and has done B.Tech.in chemical engineering. She is a Regulatory expert and currently working with Uflex Limited, Chemical Division, Noida.

Mr. Prem Kumar Nautiyal, a post graduate and M. Phil in Chemistry along with Certified Black Belt and PGDMM with 32 years of industrial experience in various industries and he is a hardcore synthetic chemist with specialty in design and development of polyurethane laminating adhesive. He is currently working with Uflex Limited (Chemical Division) as HOD- R & D- Accountable for development of new formulations and products.

It must be noted that no single analytical method is able to detect all possible migratable NIAS. Different screening approaches need to be applied for different groups of substances. A combination of several screening approaches will yield the maximum of information. The more is known about IAS, the better the chances to identify NIAS because then the screening methods applied can be adapted to the physical and chemical properties of the groups of substances expected.

2. Analytical Approaches for Analysis of Safety ofModern Food Packaging: A Review ; by MagdalenaWrona and Cristina Nerín ;Department of Analytical Chemistry, Aragon Institute of Engineering Research I3A, University of Zaragoza,María de Luna, 3, 50018 Zaragoza, Spain; Molecules 2020, 25, 752; doi:10.3390/molecules25030752 ; www.mdpi.com/journal/molecules.

3. Review of analytical approaches for the identification of non-intentionally addedsubstances in paper and board food contact materials, by Ruud J.B. Peters, Iris Groeneveld, Patricia Lopez Sanchez, WouterGebbink, ArjenGersen, Monique de Nijs, Stefan P.J. van Leeuwen ; Trends in Food Science & Technology,https://doi.org/10.1016/j.tifs.2018.12.010.

4. Articles from Packaginglaw.com; A resource provide by Kehller and Heckman LLP.

5. EuPIA Guidance on Migration Test Methods for the evaluation of substances in printing inks and varnishes for food contact materials ; 2017-07-31 ; European Printing Ink Association · EuPIA - a sector of CEPE aisbl ;www.eupia.org.

6. Dutra, C.; Pezo, D.; de AlvarengaFreire, M.T.; Nerín, C.; Reyes, F.G.R. Determination of volatileorganiccompounds in recycled polyethylene terephthalate and high-density polyethylene by headspace solid phasemicroextraction gas chromatography mass spectrometry to evaluate the e_ciency of recycling processes.J. Chromatogr. A 2011, 1218, 1319–1330.

7. Analytics of Substances in Food Packaging Material: C. Gehring https://analyticalscience.wiley.com/do/ 10.1002/gitlab.16086.

Disclaimer: The views expressed are solely the corresponding author’s personal opinion. Uflex Ltd will not accept any liability for any loss or damage that may occur from the use of this information nor do we offer a warranty against patent infringement.

Abstract

Conventional printing inks, adhesives and polymer-based packaging materials have several harmful effects on ecological aspects as well as human well-being.Expressions of concern about impurities in food contact materials have increased over the last few years. Chemical compounds that are incorporated within polymeric materials to improve functionality, may interact with food components during processing or storage and migrate into the food. Food contact materials (FCM) may contain intentionally added substance (IAS) and non-intentionally added substance (NIAS) which comes from reaction by-products, breakdown or degradation products; impurities from raw materials used their production, chemical reaction between packaging materials and foodstuff, side products or neoformed compounds and contaminants picked up during the production and recycling process.

Chemical migration of intentionally added substance (IAS), non-intentionally added substance (NIAS), and not listed substance (NLS) from food packaging is affected by a number of parameters including the nature and complexity of foods, contact time and temperature of the system, type of packaging contact layer, and properties of IAS , NIAS and NLS.

New packaging development requires a safety evaluation which helps to mitigate potential health risks, which always implicate the application of complex analytical methods. This article provides a comprehensive overview of migration theory and analytical approach towards identification of migrated IAS, NIAS, and NLS by different analytical strategies.

Keywords: NIAS, IAS, Food Packaging, Migration, Impurities.

* Corresponding author (Email: pinaki.chem@uflexltd.com)

** www.uflexltd.com

1. Introduction

Food Packaging is a rapidly evolving field. The purpose of food contact materials (FCM) are to keeping foods safe from contamination and retaining the nutritional properties and sensory characteristics of foods, packaging provides additional features that are important to consumers.Packaging encompasses a wide range of material types across plastics, glass, metal, and paper. Due to their chemical structure and properties, the most applied materials in the food industry are plastics. In addition to traditional petroleum-based polymers, biodegradable plastics and biopolymers can also be found today on the market. It should be highlighted that food contact materials (FCM) can be very complex structures created with the application of adhesives. Multi layers can not only be composed of polymers but also paper and/or aluminum that are often coated by adhesives and printing inks.

Modern society requires modern solutions, especially in the area of food safety and thus food packaging.

Food contact materials (FCM) include all materials and articles intended to come into contact with food. The FCM is produced from raw materials and so-called intentionally added substances (IAS) which increase shelf-life but also enhance the manufacturing, stability, and mechanical properties of the FCM itself.

IAS includes organic pigments, oligomers, low molecular weight resins, monomers, prepolymers, antioxidants, lubricants, surfactants, photoinitiators, and UV stabilizers. In addition to IAS, FCMs may also contain non-intentionally added substances (NIAS) which originate from reaction by-products, oligomers, degradation processes, chemical reactions between the packaging materials and the foodstuff, or as impurities from the raw materials used for their production. FCM of flexible packaging incorporated with chemical compounds is commonly referred to as plastics. Incorporation of low-molecular-weight chemical compounds improves the functional properties of plastics. However, the potential influence of these substances on product safety and quality remain in question when the amount of these migrating compounds in food exceed their specified limits. The term “migration” refers to the diffusion of substances from a zone of higher concentration (the food-contact layer) to one of a lower concentration (usually the food surface). This process is often influenced by food-packaging interactions (Arvatoyannis and Bosnea 2004) and the temperature of the system.

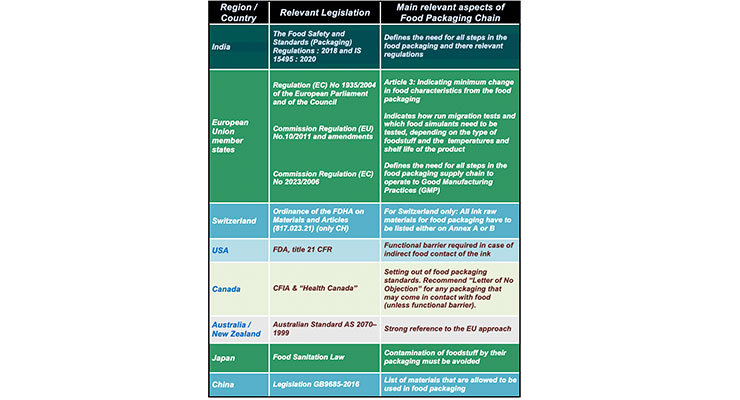

The phenomenon of IAS and NIAS is not new, but has raised awareness since they were specifically mentioned in Article 19 of Regulation EU 10/2011 (European Commission, 2011). This Regulation states that: “NIAS are permitted in final plastic articles but should be assessed by the manufacturer in accordance with internationally recognized scientific principles on risk assessment.” On January 28, 2016, the European Food Safety Authority (EFSA) Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids concluded that the required toxicity data for substances in FCM’s (IAS and NIAS) should be related to the expected human exposure and proposed three threshold levels of human exposure as triggers for requiring additional toxicity data: 1.5, 30 and 80 μg/kg body weight/day (EFSA, 2016). However, often a quantitative analysis of NIAS is not possible since reference standards are not available [1-7].

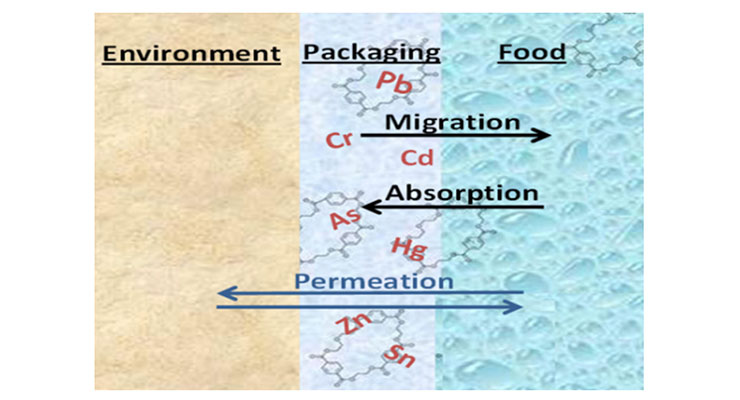

2. Migration

The mass transfer from an external source into food by sub-microscopic processes i.e. Chemical partitioning from the packaging into the food is known as migration. Migration is of relevance for smaller size compounds (below 1000 Dalton Molecular Weight.2A. Mechanism of Migration

The migrant has a high diffusion coefficient in the material and is readily dissolved into the contacting the food phase. The migrant is of low diffusion in the material at the initial contact with food. It attains a high diffusion coefficient only after some food components have been adsorbed and diffused into the film (SWELLING): dual-mode interaction.• Diffusion of migrant in package wall toward package/food interface. Frequently this is the slowest or rate-determining step of migration. In a dual interactive mode, concurrent penetration of solvent or food ingredient may change the package wall structure to a swollen state increasing the mobility of migrants.

• Dissolution of migrants at package/food interface. The dissolution depends on the affinity of migrants to the package phase and food phase.

• Dispersion or diffusion of migrants into food. The migrant will then disperse into liquid foods or diffuse into solid foods.

Schematic Diagram of Migration Mechanism as follows:

2B. The extent to which migration occurs depends on vario factors

• Molecular size of the migrants.• Temperature

• Time

• Nature/Composition of Food

• Nature/Structure of packaging

• Amount of Migratable substance in Packaging.

• Ratio between packaging surface area and volume / Weight of packaged food.

FACTORS AFFECTING MIGRATION us

2C. Types of Migration

Through Migration - Diffusion of un-polymerized ingredients through the substrate.Set-Off - The transfer of un-polymerized ingredients from the print surface to the food contact surface. Examples are labels that are rolled up on them, or cylindrical containers that are stacked with the outer printed surface of one container coming in contact with the inner surface of the next in the stack.

Vapor Phase - Ink compounds and substrates that are volatilized through heating, allowing compounds to permeate through the packaging. An example would be a microwave meal that you leave the printed top on when cooking.

Condensation Extraction - Condensation of ink compounds during cooking or factory sterilization through steam distillation.

2D. What can migrate?

IAS – Intentionally Added Substance• Positive lists or inventory lists of all the known ingredients need to make the food contact materials – monomer, additives, processing aids, solvents etc.

NIAS – Not Intentionally Added Substance

• Isomers and impurities of known ingredients.

• Reaction Products and Breakdown Products of these ingredients (formed during thermal polymerizations, thermal processing, action of heat, light on the FCM).

• Other impurities especially those coming from recycling.

Non-Listed Substances (NLS)

Non-listed substances (NLS) are another category of chemical substances which must be considered within food contact risk assessment studies. NLS are generally classed as substances that have not been listed as they have been deemed to be not harmful due to arbitrary reasons or commercial reasons, however, they are still subject to assessment. A typical example in printing inks would be pigment additives.IAS, NIAS and NLS are always present in Food Contact Materials and they can potentially migrate into foods. They migrate due to heterogeneous medium with free volume and thermal motion of chain segments. It may free, not covalently bonded, molecular mass lower than 1000 Dalton, Chemically nature different from medium, Dimensions with respect

to medium.

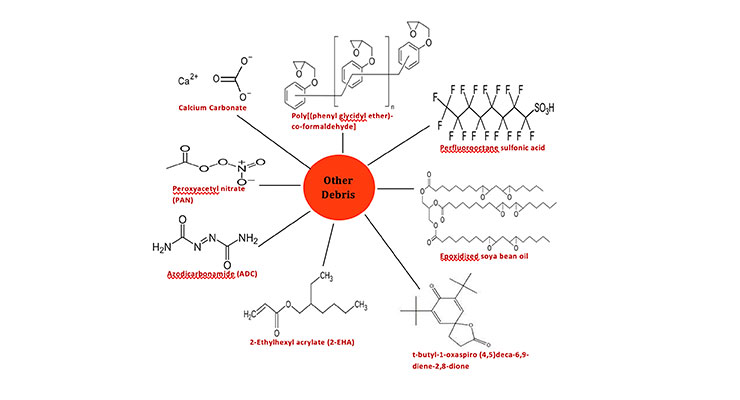

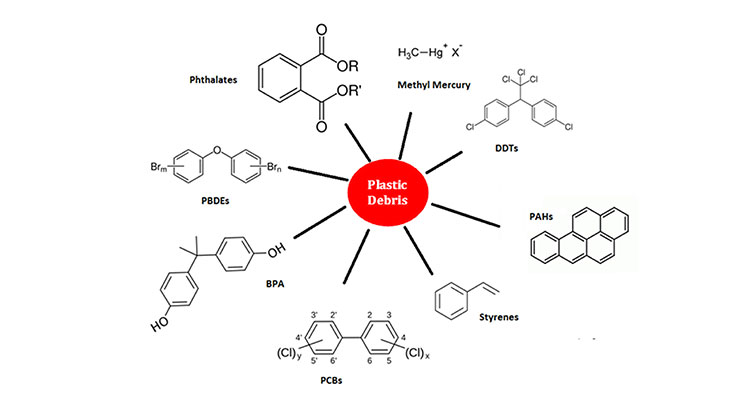

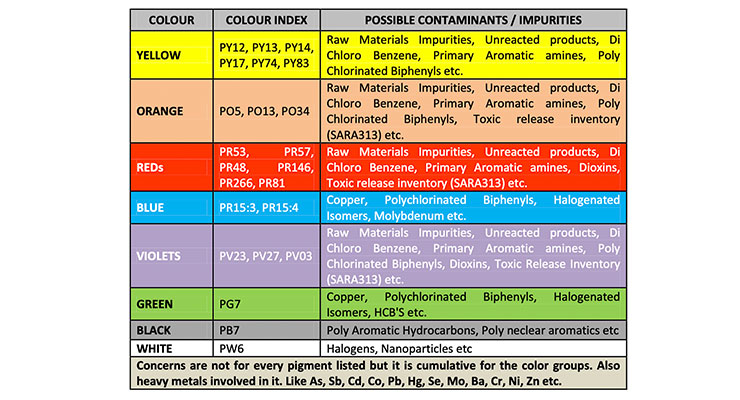

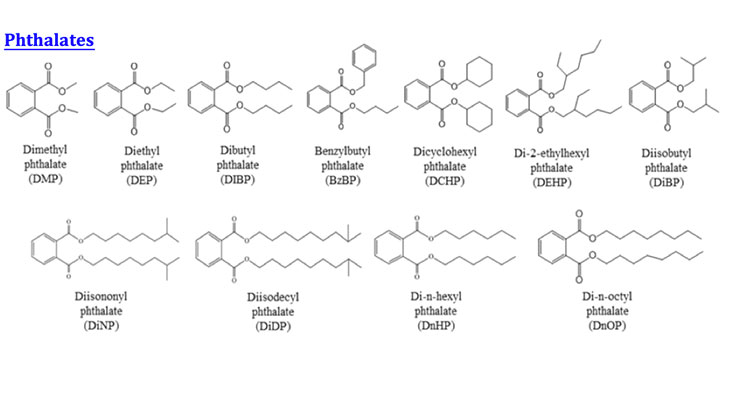

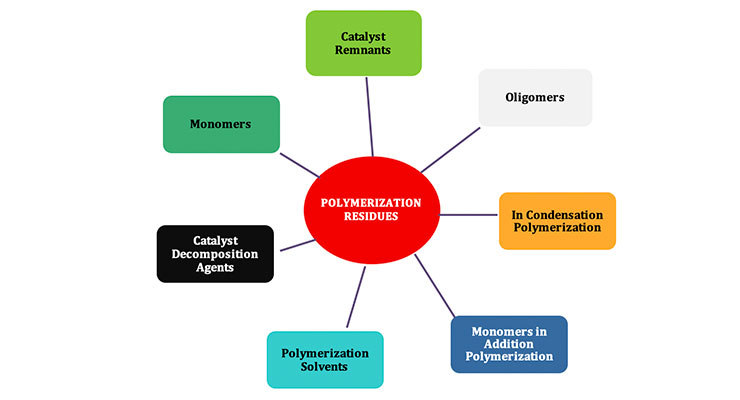

Plastics/ Printing Inks/ Laminating adhesives (Food Contact Materials) Debris:

4. NIAS Types / classification

Non Intentional Added Substance (NIAS) can vary and can be classified as (a) Reaction by products (b) Breakdown or degradation products/polymer matrix (c) Impurities from raw materials or primary chemicals (d) Products of reaction between polymer components or reaction of polymer with food (e) Degradation of additives (f) Degradation of food and packaging materials through natural aging (g) Degradation through sterile or other heating process (h) Contaminants from recycle materials (i) Neo–formed product due to environmental conditionor aging.

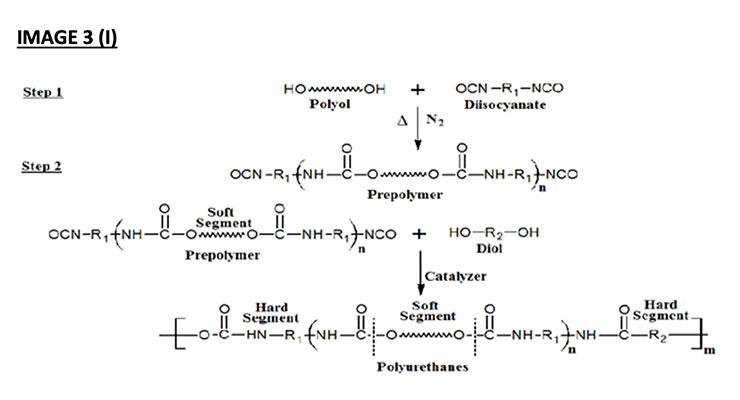

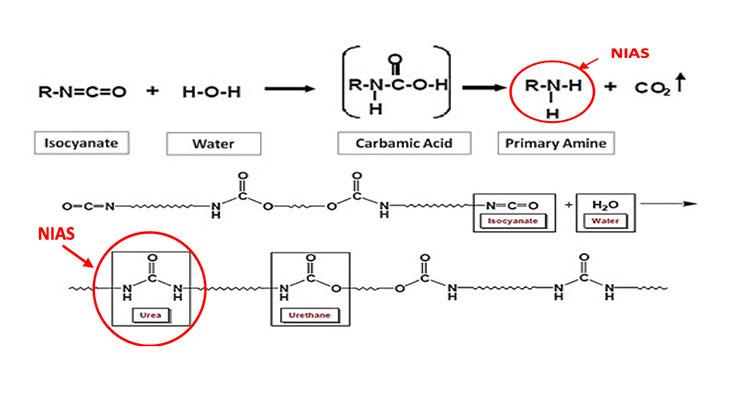

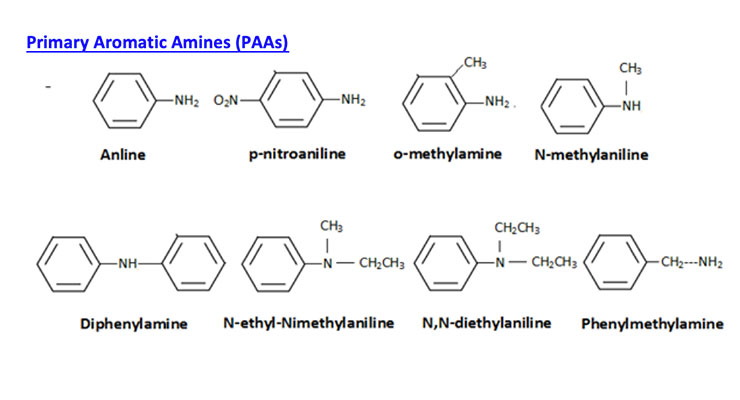

An example of neo-formed NIAS are Poly Aromatic Amines (PAAs) in polyurethane (PU) adhesives. PU adhesives are formed by the polymerization of polyols and diisocyanate monomers. If the adhesive has not been properly cured or if the ingredients have not been properly mixed, the polymerization reaction is not efficient enough and the remaining non-polymerized aromatic isocyanates can produce PAAs in contact with moisture. In addition to PAAs, other NIAS may be formed from laminatingadhesives Epoxy-based oligomers may contain bisphenol A (BPA) and bisphenol A diglycidyl ether (BADGE).

To be continued...

Acknowledgement

The authors are overwhelmed in all humbleness and gratefulness to acknowledge for written this article to Uflex management who helped to put these ideas well above the level of simplicity and something concrete. We are thankful to Uflex Ltd- Chemical Division for providing infrastructure and constructive criticism which have helped ours to accomplish this work. It is a genuine pleasure to express our deep sense of thanks and gratitude to our colleagues for their timely advice, meticulous scrutiny, scholastic advice and scientific approach to a verygreat extent.

Authors

Dr. Pinaki Ranjan Samanta has more than 26 years of experience in the areas associated to Industrial research of coating and testing of Finished products and Raw Materials of coating-related products. He received M. SC and Ph. D in the field of organic chemistry, also done PG diploma in paint technology.Dr. Manisha, Masters in chemistry from IIT and Ph.D in chemistry with more than 9 years of experience in the field of Analytical and Polymer Analysis is currently with Uflex Limited, Noida as manager (R&D).

Ms. Ritu Gupta, Masters in Chemistry, is currently working with Uflex Limited, Noida as chemist (R&D instrumentation). She has research experience of more than two years with the expertise in the area of analysis by using state-of-the-art instruments like Py- GC-MS, GC-HS, FTIR, UV-spectrophotometer etc.

Ms. Shweta Chauhan is an engineering graduate and has done B.Tech.in chemical engineering. She is a Regulatory expert and currently working with Uflex Limited, Chemical Division, Noida.

Mr. Prem Kumar Nautiyal, a post graduate and M. Phil in Chemistry along with Certified Black Belt and PGDMM with 32 years of industrial experience in various industries and he is a hardcore synthetic chemist with specialty in design and development of polyurethane laminating adhesive. He is currently working with Uflex Limited (Chemical Division) as HOD- R & D- Accountable for development of new formulations and products.

It must be noted that no single analytical method is able to detect all possible migratable NIAS. Different screening approaches need to be applied for different groups of substances. A combination of several screening approaches will yield the maximum of information. The more is known about IAS, the better the chances to identify NIAS because then the screening methods applied can be adapted to the physical and chemical properties of the groups of substances expected.

11. Reference

1. Printing ink, polymers and food packaging – Insight into the unique challenge and vulnerability towards compliance of materials and global regulatory issues - Part 1 and Part 2; by Dr. Pinaki Ranjan Samanta, Dr. Ruchi Gupta, Ms. Ritu Gupta, Ms. Shweta Chauhan and Mr. Anuj Johri ; April –May 2020: www.polymerspaintcolourjournal.com/issues or www.coatingsgroup.com.2. Analytical Approaches for Analysis of Safety ofModern Food Packaging: A Review ; by MagdalenaWrona and Cristina Nerín ;Department of Analytical Chemistry, Aragon Institute of Engineering Research I3A, University of Zaragoza,María de Luna, 3, 50018 Zaragoza, Spain; Molecules 2020, 25, 752; doi:10.3390/molecules25030752 ; www.mdpi.com/journal/molecules.

3. Review of analytical approaches for the identification of non-intentionally addedsubstances in paper and board food contact materials, by Ruud J.B. Peters, Iris Groeneveld, Patricia Lopez Sanchez, WouterGebbink, ArjenGersen, Monique de Nijs, Stefan P.J. van Leeuwen ; Trends in Food Science & Technology,https://doi.org/10.1016/j.tifs.2018.12.010.

4. Articles from Packaginglaw.com; A resource provide by Kehller and Heckman LLP.

5. EuPIA Guidance on Migration Test Methods for the evaluation of substances in printing inks and varnishes for food contact materials ; 2017-07-31 ; European Printing Ink Association · EuPIA - a sector of CEPE aisbl ;www.eupia.org.

6. Dutra, C.; Pezo, D.; de AlvarengaFreire, M.T.; Nerín, C.; Reyes, F.G.R. Determination of volatileorganiccompounds in recycled polyethylene terephthalate and high-density polyethylene by headspace solid phasemicroextraction gas chromatography mass spectrometry to evaluate the e_ciency of recycling processes.J. Chromatogr. A 2011, 1218, 1319–1330.

7. Analytics of Substances in Food Packaging Material: C. Gehring https://analyticalscience.wiley.com/do/ 10.1002/gitlab.16086.

Disclaimer: The views expressed are solely the corresponding author’s personal opinion. Uflex Ltd will not accept any liability for any loss or damage that may occur from the use of this information nor do we offer a warranty against patent infringement.