Anthony Locicero, Associate Editor05.11.18

Craft, independent and microbrewers are using creative packaging on both cans and bottles as a way for their products to stand out on the shelves. Even when the cans are available only at the source, a label or design printed directly to the substrate helps provide an identity – an instantly recognizable image and brand.

“With more craft breweries selling thousands of brands at retail, the beer choices for consumers are seemingly endless,” Weber Packaging’s Linda Roser said. “New beer varieties are constantly entering the marketplace and shelf space is at a premium. Breweries are relying on package differentiation to grab consumers’ attention at the retail point of sale.”

“Craft brewers need to obtain the biggest bang for their buck when sharing shelf space next to the ‘big beer’ brands of the retail world,” said Kim Young, Inland Packaging’s marketing communications specialist.

Added Megan Easterling, marketing manager for Ball’s North & Central American metal beverage packaging business: “High-quality graphics and eye-catching labels are brought to life by inks and finishes. They help set brands apart in the cooler and on the retail shelf.”

It’s not just the consumer that feels that way.

“Most local craft beer shops have hundreds or even thousands of options, making it overwhelming for anyone to decide what to buy,” said Dean McKeever, a freelance illustrator whose designs have graced cans from Charlton, MA-based Tree House Brewing Company. “Most of the time people will narrow their search down by beer type, and from there they make a choice based on which label they enjoy the most.”

Bart Watson, chief economist for the Brewers Association, noted that the biggest shift from 2016 to 2017 in regards to craft beer packaging is the “continued increase in share by cans.” He estimated that craft brewer production volumes are roughly 58.6% packaged (versus 41.4% draught).

“Cans rose to 16.7% of total craft production, against 41.9% for bottles, meaning that cans are 25.8% of packaged production,” Watson said.

“A premium eye-catching can design will influence a brand’s overall sales from shelf decisions, so it’s important [that] craft brewers have achievable color expectations and get accurate, consistent and reproducible color,” INX International Ink Co. Project Specialist Sarah Jacks said.

Added Paul Fennessy, director, graphics, North America – Beverage Division, Crown Cork & Seal, USA Inc., “It’s the company’s billboard. They can use the entire can as a marketing piece.”

Put a label on it

The growth in the use of cans is a recent change.

“Historically craft brewers have found that preprinted cans require a significant minimum order, which can put craft brewers at risk of graphics becoming obsolete, and ultimately limiting them from what they do best: brew beer,” Young said.

“As the craft beer industry has exploded, so has demand for screen-printed cans. This has caused the big can suppliers – namely Ball and Crown Cork – to increase the minimum order size for custom, screen printed cans,” Blue Label Digital President Andrew Boyd said. “While it might make sense to order truckloads of screen printed cans for some breweries, other breweries don’t have space or may release special editions or small-batch beers.

“Labels on cans – or bottles – allows the brewery to buy a large quantity of ‘generic’ cans, and then label them appropriately in much smaller batches,” Boyd continued. “This also eliminates the possibility of spoilage. If a screen printed can needs changes, you are stuck with a large quantity.”

For Fairfield, NJ’s Magnify Brewing, labels are cost-effective for the amount of beer it produces.

“The sticker labels that we put on blank cans allows us to experiment and do small-batch beers,” said Eric Ruta, the brewery’s founder and president.

Same goes for Alementary, based in Hackensack, NJ.

“We’re a smallish brewery and while we definitely produce enough of our core products to go with screen printed cans, those typically have to be ordered by the multiple pallet,” said Michael Roosevelt, co-owner and chief scientist. “It would take us a long time to go through a truckload of screen printed cans – and we don’t have the space to store them.”

It’s also not ideal for startups.

“We are a relatively new company still tweaking our branding,” added Kevin Sharpe, president and founder of Dark City Brewing Company, Asbury Park, NJ. “Our batches are small and we mix up what we are putting in cans so frequently it doesn’t make sense when you look at the minimum orders for printed cans. We also don’t have room to store pallets of spare printed cans.”

The use of labels fits NJ-based Bolero Snort’s business model, according to founder and president Bob Olson Jr.

“As a gypsy brewer, we are constantly brewing in multiple locations so direct print cans would become a logistical issue. Plus, we’re not at the volume on any single given brand at any single host site to commit the type of resources to printed cans,” said Olson, whose company is opening a brewery in Carlstadt, NJ in 2019. “The consumer also likes different beers constantly, so labels give us a lot more flexibility to keep an ever-rotating batch of SKUs (stock keeping units) going.”

“The use of labels provides the option to run smaller quantities across multiple brand flavors and to put their investment towards their label spend rather than into a large commitment of isolated preprinted cans, which run the risk of changing in the future,” said Inland’s Young.

Added Boyd: “Labels on cans or bottles allow breweries to rapidly adapt their packaging to immediate demands of the marketplace.”

But how’s it look?

Even when the beer is only available for purchase from the brewery, the exterior appearance is still just as important.

“Whether our can is on a shelf or not, we want it to be bold and stand out,” Magnify’s Ruta said. “I think it’s pretty evident which cans are ours, with our design and layout. Whether it’s in your fridge, cooler or on a shelf, we like keeping it clean, bold and identifiable.”

“The power of good printing and color can sway a person on what they want to buy,” said Thomas Ness, art director and illustrator for Voodoo Brewing Company, Meadville, PA. “You can really get some great bold colors with label printing.”

Added Shane Pearson of Indianapolis-based Daredevil Brewing Company: “Our approach to label design is focusing on clean designs that help us communicate what the product is as well as clearly communicating the name of the beer and style of the beer.”

Brewers have options: buy blank cans – Olson, for example, purchases his from Iron Heart – and produce shrink sleeve or pressure sensitive labels. R.B. Dwyer, Label Value, Inland Packaging, and WindWalker are amongst the label companies offering shrink sleeves.

These choices have “opened the doors for brewers to expand their portfolio and embrace versatility across their brews,” Young said.

John Linn, marketing director for Oakland Park, FL-based Funky Buddha Brewery, agrees.

“With cans, there are certainly some benefits of using labels – particularly shrink applications – including flexibility with quantity and speed to market,” he said. “Technology has come a long way recently in making these options look as good, if not better than, printing directly to can.”

“Wrapped cans provide fast, flexible solutions for can packaging,” added Dan Pressler, the creative coordinator for Coronado Brewing Company, Coronado, CA, which also employs direct-to-can printing. “You have a smaller minimum order with a variety of print options. If you’re short on space, have smaller runs in mind, or are constantly releasing cans with different artwork, then I would suggest wrapped cans over the substrate.”

LabelValue prints shrink sleeve labels with minimums as low as 1,000 sleeves, according to Josh Dickson, marketing and prepress manager.

“Shrink sleeves offer much greater flexibility and cash-flow management for craft brewers,” he said. “Especially when you consider that most craft breweries like to leverage the novelty and urgency of seasonal, small-batch or limited edition brews, shrink sleeve labeling enables them to do this optimally and with beautiful results.

“A 360° degree shrink sleeve label is more visually striking than a traditional pressure-sensitive label and provides more product coverage,” Dickson added. “Whereas pre-printed cans are limited in the number of colors that can be used and the quality of the print on the can suffer due to trapping and dot-gain, shrink sleeve labels can use unlimited numbers of colors and when printed digitally, can have crisp, clean line-art and text.”

More than looks

Sometimes it goes beyond just catching the consumer’s eye.

“Feel has become more and more important in the spirits/beer marketplace,” said Michael Moran, WindWalker Label’s VP of sales and marketing. “Seventy-four percent of people are more apt to purchase if they pick the product up.”

According to Moran, WindWalker produces labels for roughly 40 breweries.

“You typically wouldn’t see the kind of label we do on a can,” he said.

The company prints on BOPP polypropylene with tactile UV standardized across the product line.

Using rotary screen printing, WindWalker is able to raise the text on labels, such as the ones for SingleCut Beersmiths of Queens, NY.

First, WindWalker lays down a metallic ink – 877 silver. There is generally a four-color process build for SingleCut’s labels – Heavy Boots of Lead, an imperial stout, is just two – before the image is added.

“Then we lay down an overall soft touch UV and then a tactile UV over the areas that are raised,” Moran said. “You get the definition of matte versus gloss. When you pick up that can you actually feel the tactile UV.”

Selecting Inks for Cans

For direct-to-can printing, INX International Ink Co. is the leader in the metal deco ink market, supplying “almost 100%” of ink that is printed onto metal cans (inside the U.S.),” according to Jim Lambert, VP of sales – ink and hardware.

“Working closely with metal decorators who produce cans for the craft brewing customers, INX, as the leader in 2-piece metal decorating inks, strives to help manage expectations, educate about the unique nature of metal decorating, and ultimately help deliver and capture what craft brewers envision on their aluminum can package,” Jacks said.

Per Jacks, the biggest challenge in getting the ink onto the cans is “meeting the brewers’ expectations of color and graphics from the design phase.”

“Many brands may already have established designs and brand elements in the marketplace for other substrates such as cartons and bottles or even store signage and displays,” she said. “When it comes to printing directly on cans, the unique nature of the grey aluminum can make it impossible to match the bright, clean colors that they see on a white label or white carton stock. Also, most craft beer designs require wet-on-wet ink screen builds to attain the desired appearance.

“Since these inks touch one another on the same blanket, cross-contamination of colors is inevitable and problematic,” Jacks added. “Finally, the inherent mechanical variation of the 2-piece decoration process makes it difficult to match dot gain and registration of these screen builds run-to-run, and even can-to-can.”

Label Printers and Print Processes

Craft beer label printers are using a mix of printing processes, including digital printing. Dion Label Printing specializes in digital and flexographic printing. Dion Label works with roughly 50 breweries and made the foray into digital printing after purchasing an HP Indigo WS4050. Six months later, the company added a second Indigo press.

“Our team was incredibly pleased with the color matching that digital provided along with the quality of print registration,” Marketing Manager Ashley Stewart said. “Dion customers embraced digital printing along with traditional flexographic printing and label business continued to grow.” Currently, the company uses two HP Indigo WS6800 presses that utilize HP ElectroInk.

In 2008, Dion purchased the first MPS servo converting press for its flexographic department, according to Stewart. A second MPS press was purchased in 2015. Dion has three additional 8-color flexographic presses. Dion also has two finishing presses that are used for coating and die cutting after being printed, Stewart added.

Inland Packaging, which works with more than 150 breweries, has eight flexographic presses between its La Crosse and Neenah, WI and Downington, PA plants. The pressure sensitive and shrink sleeve operations are primarily produced at the Neenah and Downingtown locations, according to Young.

“We have the capacity to run between eight and 10 stations of water-based or UV ink,” she said, adding the company’s newest flexo press was installed at the end of 2016.

Last spring, Inland Packaging installed its first digital press – an HP Indigo 20000 – at its Neenah plant. The company has been producing shrink sleeves through its digital press, which provides additional labeling alternatives for craft brewers.

“One of the main selling points when selecting this press was its ability to efficiently produce small production runs,” Young explained. “This provides craft brewers the ability to order small quantities of seasonal labels or run promotional labels at the quantity they need rather than having the requirement of a minimum quantity that surpasses their true need. These situations put them at risk of having their graphics become out of date or obsolete.

“The second aspect of our digital press we have been embracing is the chance to customize label graphics throughout production,” Young continued. “This theory is that variable packaging truly aligns with what brand owners and consumers are wanting to see out in the market. Graphics can be created with varying images or data on the label, which engages consumers further than their last sip of beer. We have found this theory is strongly embraced amongst the millennial generation. They enjoy being engaged with a product as much as they enjoy the product itself. Utilizing packaging to deliver a unique experience each time they enjoy their beverage of choice by redirecting them to the brewery’s social media or initiate an action like ‘share a selfie’ with us, can build engagement on their sites. If a person is looking for a new brewery to visit, a new brew, or something fun to do on a Friday night, our first step is the internet or social media. So, why not incorporate it into their graphics to make it more convenient and customizable?”

WindWalker runs three 13-inch Nilpeter presses, a 17-inch Nilpeter press, as well as seven Mark Andy presses. According to Moran, the company is installing a hybrid – digital and flexo – press with a seven-color digital head. The new press will allow for cold and hot foil printing, cast and cure and will come with turn bars. The presses are configured to run water-based and UV-based inks. WindWalker uses Actega inks.

Blue Label Digital provides services for nearly 700 breweries, according to Boyd. The company prints exclusively with digital presses – HP Indigo in this case.

“We start with vector-based artwork from our customers and their design teams,” Boyd said. “Once we’ve cleaned up and standardized the artwork, we send it to our digital press using a raster image processor, which essentially turns the design into a series of dots.

“The Indigo printer then creates the artwork on a digital plate using electric, which pulls the ink to it using electrical charges,” he continued. “The image created is then pressed onto the paper. After that, the whole thing happens again, for every single impression the press makes. This means that every image coming off of the press can be totally different. There is no need for plates, as everything is created using electrical charges.

“After we have printed a roll of material, it is taken to a finishing line to be foil stamped, laminated, varnished, or whatever other techniques are necessary to create the look and die cut,” Boyd concluded. “Our customers receive rolls of finished pressure sensitive labels.”

LabelValue, which creates labels for roughly 25 breweries mainly in the Tampa Bay, FL area, uses HP ElectroInks, CMYKOVG + White. Equipment-wise, the company uses an HP Indigo WS6800 Series digital press for printing the shrink sleeves.

“The ElectroInk that we use for our shrink sleeves is a liquid ink that can be printed as small as 1-2 microns in particle size,” Dickson said. “This means that we can maintain sharp edges, clean text and striking images throughout the print run. With the 7 color inks (CMYKOVG) + white ink that we can use, we can ensure maximum color accuracy and create stunning color with the shrink sleeves. We use the white ink as a backing, which plays an important role in keeping the clear shrink sleeve substrate opaque, to prevent any muddying of the design due to the mixture of the aluminum can and the clear substrate. The inks are actually reverse printed on the back side of the sleeve material, and they show through the clear material after being applied to the container.”

Can it!

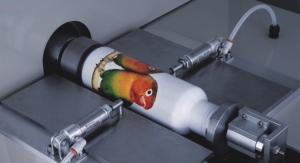

Unlike other packaging, cans are formed from a coil of aluminum, and the design is printed on the can while on the high-speed production line.

Ball’s Easterling spoke to the advantages of printing direct-to-can.

“By printing directly on the can with standard inks, or by using Ball’s specialty inks or finishes, brewers can position their beverage as a premium product in a premium package,” she said. “Also, not having to post-label the cans removes added costs, time and complexity, leaving more time to brew great beer.”

“It’s the most optimized technology for efficiency and cost, whether you’re a small or large CPG [consumer packaged goods] company,” Crown’s Fennessy said.

While Funky Buddha’s Linn spoke the praises of using labels, he’s not opposed to printing direct-to-can.

“Right now, we chose to print direct-to-can though, namely because of a couple of factors: equipment, pricing, and the brands produced,” he said. “In terms of the latter, the brands we are canning initially include our year-round products that sell well, have well-planned forecasts and are not in danger of being replaced or removed from the market. Once we begin packaging some of the deeper parts of our portfolio I’m certain we’ll look more closely at shrink applications, particularly through a number of vendors who are now fulfilling themselves. The cost will remain a factor.”

“We don’t use labels for a few reasons,” said Marty Shutter, marketing director, Ozark Beer Company, Rogers, AR. “First off, we’ve grown our packaged product line very slowly, adding only one can a year in four years. Obviously, we also save money per can.

“Ultimately, it’s a bit of branding, a bit of a waste issue, a bit of a cost issue and a bit of our business model,” he added.

Said Sarah Hedlund, Decorah, IA-based Toppling Goliath’s marketing director/artist: “I like the look and feel of the direct-to-can printing compared to some of the other options.”

Shutter noted that Ozark does two small batch releases per year that is labeled with a sticker.

“Those are way too small to justify a can design, and honestly the beers themselves have begun to take on a life of their own despite their lack of design,” he said.

INX partnered with CMA Imaging to provide color proofing capabilities – flat and round – for beverage cans.

“A whole new market is appearing because of craft brewers,” Lambert said. “Let’s say you’re a craft brewer. You have a brand-new can. You can’t go to one of the conventional can (manufacturers) and say, ‘I want to see what this looks like.’ They’d have to put it on the production line. We have a machine – the CP800 Can Printer – and ink that sticks to beverage cans that they can proof them, ensuring that those colors you see in the proof are what you get on the production line.”

Ink and its role

Crown employs a dry offset process, according to Fennessy. This includes six different plates with six different colors (each ink is a different color). Inks are kept separately in inkwells to avoid contamination, he said.

Rollers transfer the ink from the inkwell to the plates one at a time to a blanket on a wheel. This transfers composite ink to cans at 2,000 cans per minute, Fennessy said.

“Inks and finishes help brands communicate in new and creative ways. The can provides a 360˚ billboard right in the consumers’ hand,” Easterling said. “The graphics our customers choose to bring beverages, flavors and occasions to life. When your product is quite literally in the hands of consumers you have a prime opportunity to showcase your individuality as a brand through what you put on the can. Graphics, by way of inks, are a brewer’s chance to communicate with their customers, fostering brand loyalty with every can a customer picks up.”

“With more craft breweries selling thousands of brands at retail, the beer choices for consumers are seemingly endless,” Weber Packaging’s Linda Roser said. “New beer varieties are constantly entering the marketplace and shelf space is at a premium. Breweries are relying on package differentiation to grab consumers’ attention at the retail point of sale.”

“Craft brewers need to obtain the biggest bang for their buck when sharing shelf space next to the ‘big beer’ brands of the retail world,” said Kim Young, Inland Packaging’s marketing communications specialist.

Added Megan Easterling, marketing manager for Ball’s North & Central American metal beverage packaging business: “High-quality graphics and eye-catching labels are brought to life by inks and finishes. They help set brands apart in the cooler and on the retail shelf.”

It’s not just the consumer that feels that way.

“Most local craft beer shops have hundreds or even thousands of options, making it overwhelming for anyone to decide what to buy,” said Dean McKeever, a freelance illustrator whose designs have graced cans from Charlton, MA-based Tree House Brewing Company. “Most of the time people will narrow their search down by beer type, and from there they make a choice based on which label they enjoy the most.”

Bart Watson, chief economist for the Brewers Association, noted that the biggest shift from 2016 to 2017 in regards to craft beer packaging is the “continued increase in share by cans.” He estimated that craft brewer production volumes are roughly 58.6% packaged (versus 41.4% draught).

“Cans rose to 16.7% of total craft production, against 41.9% for bottles, meaning that cans are 25.8% of packaged production,” Watson said.

“A premium eye-catching can design will influence a brand’s overall sales from shelf decisions, so it’s important [that] craft brewers have achievable color expectations and get accurate, consistent and reproducible color,” INX International Ink Co. Project Specialist Sarah Jacks said.

Added Paul Fennessy, director, graphics, North America – Beverage Division, Crown Cork & Seal, USA Inc., “It’s the company’s billboard. They can use the entire can as a marketing piece.”

Put a label on it

The growth in the use of cans is a recent change.

“Historically craft brewers have found that preprinted cans require a significant minimum order, which can put craft brewers at risk of graphics becoming obsolete, and ultimately limiting them from what they do best: brew beer,” Young said.

“As the craft beer industry has exploded, so has demand for screen-printed cans. This has caused the big can suppliers – namely Ball and Crown Cork – to increase the minimum order size for custom, screen printed cans,” Blue Label Digital President Andrew Boyd said. “While it might make sense to order truckloads of screen printed cans for some breweries, other breweries don’t have space or may release special editions or small-batch beers.

“Labels on cans – or bottles – allows the brewery to buy a large quantity of ‘generic’ cans, and then label them appropriately in much smaller batches,” Boyd continued. “This also eliminates the possibility of spoilage. If a screen printed can needs changes, you are stuck with a large quantity.”

For Fairfield, NJ’s Magnify Brewing, labels are cost-effective for the amount of beer it produces.

“The sticker labels that we put on blank cans allows us to experiment and do small-batch beers,” said Eric Ruta, the brewery’s founder and president.

Same goes for Alementary, based in Hackensack, NJ.

“We’re a smallish brewery and while we definitely produce enough of our core products to go with screen printed cans, those typically have to be ordered by the multiple pallet,” said Michael Roosevelt, co-owner and chief scientist. “It would take us a long time to go through a truckload of screen printed cans – and we don’t have the space to store them.”

It’s also not ideal for startups.

“We are a relatively new company still tweaking our branding,” added Kevin Sharpe, president and founder of Dark City Brewing Company, Asbury Park, NJ. “Our batches are small and we mix up what we are putting in cans so frequently it doesn’t make sense when you look at the minimum orders for printed cans. We also don’t have room to store pallets of spare printed cans.”

The use of labels fits NJ-based Bolero Snort’s business model, according to founder and president Bob Olson Jr.

“As a gypsy brewer, we are constantly brewing in multiple locations so direct print cans would become a logistical issue. Plus, we’re not at the volume on any single given brand at any single host site to commit the type of resources to printed cans,” said Olson, whose company is opening a brewery in Carlstadt, NJ in 2019. “The consumer also likes different beers constantly, so labels give us a lot more flexibility to keep an ever-rotating batch of SKUs (stock keeping units) going.”

“The use of labels provides the option to run smaller quantities across multiple brand flavors and to put their investment towards their label spend rather than into a large commitment of isolated preprinted cans, which run the risk of changing in the future,” said Inland’s Young.

Added Boyd: “Labels on cans or bottles allow breweries to rapidly adapt their packaging to immediate demands of the marketplace.”

But how’s it look?

Even when the beer is only available for purchase from the brewery, the exterior appearance is still just as important.

“Whether our can is on a shelf or not, we want it to be bold and stand out,” Magnify’s Ruta said. “I think it’s pretty evident which cans are ours, with our design and layout. Whether it’s in your fridge, cooler or on a shelf, we like keeping it clean, bold and identifiable.”

“The power of good printing and color can sway a person on what they want to buy,” said Thomas Ness, art director and illustrator for Voodoo Brewing Company, Meadville, PA. “You can really get some great bold colors with label printing.”

Added Shane Pearson of Indianapolis-based Daredevil Brewing Company: “Our approach to label design is focusing on clean designs that help us communicate what the product is as well as clearly communicating the name of the beer and style of the beer.”

Brewers have options: buy blank cans – Olson, for example, purchases his from Iron Heart – and produce shrink sleeve or pressure sensitive labels. R.B. Dwyer, Label Value, Inland Packaging, and WindWalker are amongst the label companies offering shrink sleeves.

These choices have “opened the doors for brewers to expand their portfolio and embrace versatility across their brews,” Young said.

John Linn, marketing director for Oakland Park, FL-based Funky Buddha Brewery, agrees.

“With cans, there are certainly some benefits of using labels – particularly shrink applications – including flexibility with quantity and speed to market,” he said. “Technology has come a long way recently in making these options look as good, if not better than, printing directly to can.”

“Wrapped cans provide fast, flexible solutions for can packaging,” added Dan Pressler, the creative coordinator for Coronado Brewing Company, Coronado, CA, which also employs direct-to-can printing. “You have a smaller minimum order with a variety of print options. If you’re short on space, have smaller runs in mind, or are constantly releasing cans with different artwork, then I would suggest wrapped cans over the substrate.”

LabelValue prints shrink sleeve labels with minimums as low as 1,000 sleeves, according to Josh Dickson, marketing and prepress manager.

“Shrink sleeves offer much greater flexibility and cash-flow management for craft brewers,” he said. “Especially when you consider that most craft breweries like to leverage the novelty and urgency of seasonal, small-batch or limited edition brews, shrink sleeve labeling enables them to do this optimally and with beautiful results.

“A 360° degree shrink sleeve label is more visually striking than a traditional pressure-sensitive label and provides more product coverage,” Dickson added. “Whereas pre-printed cans are limited in the number of colors that can be used and the quality of the print on the can suffer due to trapping and dot-gain, shrink sleeve labels can use unlimited numbers of colors and when printed digitally, can have crisp, clean line-art and text.”

More than looks

Sometimes it goes beyond just catching the consumer’s eye.

“Feel has become more and more important in the spirits/beer marketplace,” said Michael Moran, WindWalker Label’s VP of sales and marketing. “Seventy-four percent of people are more apt to purchase if they pick the product up.”

According to Moran, WindWalker produces labels for roughly 40 breweries.

“You typically wouldn’t see the kind of label we do on a can,” he said.

The company prints on BOPP polypropylene with tactile UV standardized across the product line.

Using rotary screen printing, WindWalker is able to raise the text on labels, such as the ones for SingleCut Beersmiths of Queens, NY.

First, WindWalker lays down a metallic ink – 877 silver. There is generally a four-color process build for SingleCut’s labels – Heavy Boots of Lead, an imperial stout, is just two – before the image is added.

“Then we lay down an overall soft touch UV and then a tactile UV over the areas that are raised,” Moran said. “You get the definition of matte versus gloss. When you pick up that can you actually feel the tactile UV.”

Selecting Inks for Cans

For direct-to-can printing, INX International Ink Co. is the leader in the metal deco ink market, supplying “almost 100%” of ink that is printed onto metal cans (inside the U.S.),” according to Jim Lambert, VP of sales – ink and hardware.

“Working closely with metal decorators who produce cans for the craft brewing customers, INX, as the leader in 2-piece metal decorating inks, strives to help manage expectations, educate about the unique nature of metal decorating, and ultimately help deliver and capture what craft brewers envision on their aluminum can package,” Jacks said.

Per Jacks, the biggest challenge in getting the ink onto the cans is “meeting the brewers’ expectations of color and graphics from the design phase.”

“Many brands may already have established designs and brand elements in the marketplace for other substrates such as cartons and bottles or even store signage and displays,” she said. “When it comes to printing directly on cans, the unique nature of the grey aluminum can make it impossible to match the bright, clean colors that they see on a white label or white carton stock. Also, most craft beer designs require wet-on-wet ink screen builds to attain the desired appearance.

“Since these inks touch one another on the same blanket, cross-contamination of colors is inevitable and problematic,” Jacks added. “Finally, the inherent mechanical variation of the 2-piece decoration process makes it difficult to match dot gain and registration of these screen builds run-to-run, and even can-to-can.”

Label Printers and Print Processes

Craft beer label printers are using a mix of printing processes, including digital printing. Dion Label Printing specializes in digital and flexographic printing. Dion Label works with roughly 50 breweries and made the foray into digital printing after purchasing an HP Indigo WS4050. Six months later, the company added a second Indigo press.

“Our team was incredibly pleased with the color matching that digital provided along with the quality of print registration,” Marketing Manager Ashley Stewart said. “Dion customers embraced digital printing along with traditional flexographic printing and label business continued to grow.” Currently, the company uses two HP Indigo WS6800 presses that utilize HP ElectroInk.

In 2008, Dion purchased the first MPS servo converting press for its flexographic department, according to Stewart. A second MPS press was purchased in 2015. Dion has three additional 8-color flexographic presses. Dion also has two finishing presses that are used for coating and die cutting after being printed, Stewart added.

Inland Packaging, which works with more than 150 breweries, has eight flexographic presses between its La Crosse and Neenah, WI and Downington, PA plants. The pressure sensitive and shrink sleeve operations are primarily produced at the Neenah and Downingtown locations, according to Young.

“We have the capacity to run between eight and 10 stations of water-based or UV ink,” she said, adding the company’s newest flexo press was installed at the end of 2016.

Last spring, Inland Packaging installed its first digital press – an HP Indigo 20000 – at its Neenah plant. The company has been producing shrink sleeves through its digital press, which provides additional labeling alternatives for craft brewers.

“One of the main selling points when selecting this press was its ability to efficiently produce small production runs,” Young explained. “This provides craft brewers the ability to order small quantities of seasonal labels or run promotional labels at the quantity they need rather than having the requirement of a minimum quantity that surpasses their true need. These situations put them at risk of having their graphics become out of date or obsolete.

“The second aspect of our digital press we have been embracing is the chance to customize label graphics throughout production,” Young continued. “This theory is that variable packaging truly aligns with what brand owners and consumers are wanting to see out in the market. Graphics can be created with varying images or data on the label, which engages consumers further than their last sip of beer. We have found this theory is strongly embraced amongst the millennial generation. They enjoy being engaged with a product as much as they enjoy the product itself. Utilizing packaging to deliver a unique experience each time they enjoy their beverage of choice by redirecting them to the brewery’s social media or initiate an action like ‘share a selfie’ with us, can build engagement on their sites. If a person is looking for a new brewery to visit, a new brew, or something fun to do on a Friday night, our first step is the internet or social media. So, why not incorporate it into their graphics to make it more convenient and customizable?”

WindWalker runs three 13-inch Nilpeter presses, a 17-inch Nilpeter press, as well as seven Mark Andy presses. According to Moran, the company is installing a hybrid – digital and flexo – press with a seven-color digital head. The new press will allow for cold and hot foil printing, cast and cure and will come with turn bars. The presses are configured to run water-based and UV-based inks. WindWalker uses Actega inks.

Blue Label Digital provides services for nearly 700 breweries, according to Boyd. The company prints exclusively with digital presses – HP Indigo in this case.

“We start with vector-based artwork from our customers and their design teams,” Boyd said. “Once we’ve cleaned up and standardized the artwork, we send it to our digital press using a raster image processor, which essentially turns the design into a series of dots.

“The Indigo printer then creates the artwork on a digital plate using electric, which pulls the ink to it using electrical charges,” he continued. “The image created is then pressed onto the paper. After that, the whole thing happens again, for every single impression the press makes. This means that every image coming off of the press can be totally different. There is no need for plates, as everything is created using electrical charges.

“After we have printed a roll of material, it is taken to a finishing line to be foil stamped, laminated, varnished, or whatever other techniques are necessary to create the look and die cut,” Boyd concluded. “Our customers receive rolls of finished pressure sensitive labels.”

LabelValue, which creates labels for roughly 25 breweries mainly in the Tampa Bay, FL area, uses HP ElectroInks, CMYKOVG + White. Equipment-wise, the company uses an HP Indigo WS6800 Series digital press for printing the shrink sleeves.

“The ElectroInk that we use for our shrink sleeves is a liquid ink that can be printed as small as 1-2 microns in particle size,” Dickson said. “This means that we can maintain sharp edges, clean text and striking images throughout the print run. With the 7 color inks (CMYKOVG) + white ink that we can use, we can ensure maximum color accuracy and create stunning color with the shrink sleeves. We use the white ink as a backing, which plays an important role in keeping the clear shrink sleeve substrate opaque, to prevent any muddying of the design due to the mixture of the aluminum can and the clear substrate. The inks are actually reverse printed on the back side of the sleeve material, and they show through the clear material after being applied to the container.”

Can it!

Unlike other packaging, cans are formed from a coil of aluminum, and the design is printed on the can while on the high-speed production line.

Ball’s Easterling spoke to the advantages of printing direct-to-can.

“By printing directly on the can with standard inks, or by using Ball’s specialty inks or finishes, brewers can position their beverage as a premium product in a premium package,” she said. “Also, not having to post-label the cans removes added costs, time and complexity, leaving more time to brew great beer.”

“It’s the most optimized technology for efficiency and cost, whether you’re a small or large CPG [consumer packaged goods] company,” Crown’s Fennessy said.

While Funky Buddha’s Linn spoke the praises of using labels, he’s not opposed to printing direct-to-can.

“Right now, we chose to print direct-to-can though, namely because of a couple of factors: equipment, pricing, and the brands produced,” he said. “In terms of the latter, the brands we are canning initially include our year-round products that sell well, have well-planned forecasts and are not in danger of being replaced or removed from the market. Once we begin packaging some of the deeper parts of our portfolio I’m certain we’ll look more closely at shrink applications, particularly through a number of vendors who are now fulfilling themselves. The cost will remain a factor.”

“We don’t use labels for a few reasons,” said Marty Shutter, marketing director, Ozark Beer Company, Rogers, AR. “First off, we’ve grown our packaged product line very slowly, adding only one can a year in four years. Obviously, we also save money per can.

“Ultimately, it’s a bit of branding, a bit of a waste issue, a bit of a cost issue and a bit of our business model,” he added.

Said Sarah Hedlund, Decorah, IA-based Toppling Goliath’s marketing director/artist: “I like the look and feel of the direct-to-can printing compared to some of the other options.”

Shutter noted that Ozark does two small batch releases per year that is labeled with a sticker.

“Those are way too small to justify a can design, and honestly the beers themselves have begun to take on a life of their own despite their lack of design,” he said.

INX partnered with CMA Imaging to provide color proofing capabilities – flat and round – for beverage cans.

“A whole new market is appearing because of craft brewers,” Lambert said. “Let’s say you’re a craft brewer. You have a brand-new can. You can’t go to one of the conventional can (manufacturers) and say, ‘I want to see what this looks like.’ They’d have to put it on the production line. We have a machine – the CP800 Can Printer – and ink that sticks to beverage cans that they can proof them, ensuring that those colors you see in the proof are what you get on the production line.”

Ink and its role

Crown employs a dry offset process, according to Fennessy. This includes six different plates with six different colors (each ink is a different color). Inks are kept separately in inkwells to avoid contamination, he said.

Rollers transfer the ink from the inkwell to the plates one at a time to a blanket on a wheel. This transfers composite ink to cans at 2,000 cans per minute, Fennessy said.

“Inks and finishes help brands communicate in new and creative ways. The can provides a 360˚ billboard right in the consumers’ hand,” Easterling said. “The graphics our customers choose to bring beverages, flavors and occasions to life. When your product is quite literally in the hands of consumers you have a prime opportunity to showcase your individuality as a brand through what you put on the can. Graphics, by way of inks, are a brewer’s chance to communicate with their customers, fostering brand loyalty with every can a customer picks up.”