By Dave Savastano, Editor03.23.15

1886 Merritt Road

Fort Mill, SC 29715

Phone: (803) 548-2210

www.wikoff.com

Sales: $175 million (Ink World estimate).

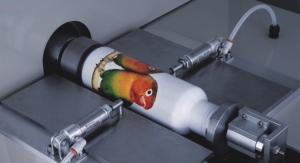

Major Products: Sheetfed and web offset inks, solvent-based and water-based flexo and gravure inks, energy-curable inks and coatings, security inks, UV inkjet inks, overprint varnish and aqueous coatings.

Geoff Peters

Key Personnel: Geoff Peters, president and CEO; Daryl Collins, VP of national sales and regional operations; Greg Burch, VP of international and security markets; Frieda Liles, VP of finance and treasurer; Buck Rorie, VP of administration; Martin Hambrock, VP of Canadian operations; Don Duncan, director of R&D; Ken Klug, director of purchasing; Art Dennis, director of manufacturing.

Comments: Wikoff Color reported a strong year of growth in 2014, with significant gains being made in sales outside of North America.

“Wikoff had another decent growth year in 2014, notwithstanding a rapidly changing packaging market influenced by regulation and industry consolidation,” said Geoff Peters, president and CEO.

“Wikoff has seen sustained growth at a large segment of our customers as well as a trend to invest back into their businesses. The packaging and label markets remained strong, while we saw a slight decline in the commercial market.

“Flexographic inks and coatings (water, energy cure and solvent) were our largest growth segments in 2014, followed by our energy cure litho and inkjet inks,” Peters added. “Wikoff made significant capital investments in manufacturing and quality control in these segments to sustain this growth.”

Peters said that Wikoff’s growth outside of North America is a major highlight from 2014.

“We have a growing network of distributors along with an operation in the United Kingdom that have contributed to this growth,” he said. “We were also very pleased with the continued expansion of our industrial inkjet business.”

In a major move, Wikoff Color announced organizational changes during 2014. Greg Burch was promoted to VP – international and security markets, and is responsible for all Wikoff sales and branch plant operations outside the U.S., including Wikoff’s Canadian operations. He is also responsible for the Alpharetta, GA branch plant and the global sales and technical support of Wikoff’s security business.

Bowman Shaw was promoted to regional VP – Midwest, West Coast. He is responsible for sales and branch plant operations for seven Wikoff manufacturing operations. Ben Price was promoted to regional manager, Southwest, where he is responsible for three manufacturing operations and one sales/service center within the Southwest region.

Ken Klug was promoted to director, purchasing, replacing Price. Klug joined Wikoff in 2007 with responsibility for implementing its Enterprise Resource Planning (ERP) applications and led the ERP implementation in all 29 current Wikoff locations.

Regulatory pressures are increasing, and ink manufacturers have to be mindful of the different standards that are in place in each country. Dr. Don Duncan, director of research for Wikoff Color, noted that Wikoff has formulated products that fully conform to all the regulatory requirements in throughout the world.

“The United States’ regulations and the EU are much the same as they have been for many years,” said Duncan. “The regulations in Switzerland, while not new, are much more stringent than in other parts of the world. The practical issue is not the regulations, but rather the desire to exceed regulatory requirements in order to meet requirement by food packaging/producing companies.

“The US regulatory position is more aligned to protect the consumer where materials that are known to be safe can migrate into food and cause no regulatory concern,” Dr. Duncan added. “In Europe, product integrity seems to be the focus of pending regulations: It does not matter so much whether a migratory chemical is safe. Rather, the position is that if the food producer didn’t put it in the food, then it doesn’t belong in the food.

“This type of ‘low migration’ thinking has become a de facto regulation,” Dr. Duncan noted. “Wikoff has developed a full line of products that meet this need, and we also have other products that fully conform to all the regulatory requirements in different parts of the world.”

As for raw materials, Klug noted that prices and supply have stabilized.

“Most raw materials have stabilized as a result of increased inventory in addition to the falling prices of crude and natural gas,” Klug said. “Unavoidable disruptions to the supply chain for scheduled and unscheduled maintenance are not a concern, but something we expect to happen from time to time and try to address in our procurement strategies.”

Peters is optimistic that Wikoff Color is well positioned for continued growth.

“Wikoff Color expects to continue our sales growth in 2015,” Peters concluded. “We made a series of organizational changes to promote our growth in international sales and the flexible packaging and label markets. We continue to look for opportunities for organic growth as well as growth through acquisition.”

Fort Mill, SC 29715

Phone: (803) 548-2210

www.wikoff.com

Sales: $175 million (Ink World estimate).

Major Products: Sheetfed and web offset inks, solvent-based and water-based flexo and gravure inks, energy-curable inks and coatings, security inks, UV inkjet inks, overprint varnish and aqueous coatings.

Geoff Peters

Comments: Wikoff Color reported a strong year of growth in 2014, with significant gains being made in sales outside of North America.

“Wikoff had another decent growth year in 2014, notwithstanding a rapidly changing packaging market influenced by regulation and industry consolidation,” said Geoff Peters, president and CEO.

“Wikoff has seen sustained growth at a large segment of our customers as well as a trend to invest back into their businesses. The packaging and label markets remained strong, while we saw a slight decline in the commercial market.

“Flexographic inks and coatings (water, energy cure and solvent) were our largest growth segments in 2014, followed by our energy cure litho and inkjet inks,” Peters added. “Wikoff made significant capital investments in manufacturing and quality control in these segments to sustain this growth.”

Peters said that Wikoff’s growth outside of North America is a major highlight from 2014.

“We have a growing network of distributors along with an operation in the United Kingdom that have contributed to this growth,” he said. “We were also very pleased with the continued expansion of our industrial inkjet business.”

In a major move, Wikoff Color announced organizational changes during 2014. Greg Burch was promoted to VP – international and security markets, and is responsible for all Wikoff sales and branch plant operations outside the U.S., including Wikoff’s Canadian operations. He is also responsible for the Alpharetta, GA branch plant and the global sales and technical support of Wikoff’s security business.

Bowman Shaw was promoted to regional VP – Midwest, West Coast. He is responsible for sales and branch plant operations for seven Wikoff manufacturing operations. Ben Price was promoted to regional manager, Southwest, where he is responsible for three manufacturing operations and one sales/service center within the Southwest region.

Ken Klug was promoted to director, purchasing, replacing Price. Klug joined Wikoff in 2007 with responsibility for implementing its Enterprise Resource Planning (ERP) applications and led the ERP implementation in all 29 current Wikoff locations.

Regulatory pressures are increasing, and ink manufacturers have to be mindful of the different standards that are in place in each country. Dr. Don Duncan, director of research for Wikoff Color, noted that Wikoff has formulated products that fully conform to all the regulatory requirements in throughout the world.

“The United States’ regulations and the EU are much the same as they have been for many years,” said Duncan. “The regulations in Switzerland, while not new, are much more stringent than in other parts of the world. The practical issue is not the regulations, but rather the desire to exceed regulatory requirements in order to meet requirement by food packaging/producing companies.

“The US regulatory position is more aligned to protect the consumer where materials that are known to be safe can migrate into food and cause no regulatory concern,” Dr. Duncan added. “In Europe, product integrity seems to be the focus of pending regulations: It does not matter so much whether a migratory chemical is safe. Rather, the position is that if the food producer didn’t put it in the food, then it doesn’t belong in the food.

“This type of ‘low migration’ thinking has become a de facto regulation,” Dr. Duncan noted. “Wikoff has developed a full line of products that meet this need, and we also have other products that fully conform to all the regulatory requirements in different parts of the world.”

As for raw materials, Klug noted that prices and supply have stabilized.

“Most raw materials have stabilized as a result of increased inventory in addition to the falling prices of crude and natural gas,” Klug said. “Unavoidable disruptions to the supply chain for scheduled and unscheduled maintenance are not a concern, but something we expect to happen from time to time and try to address in our procurement strategies.”

Peters is optimistic that Wikoff Color is well positioned for continued growth.

“Wikoff Color expects to continue our sales growth in 2015,” Peters concluded. “We made a series of organizational changes to promote our growth in international sales and the flexible packaging and label markets. We continue to look for opportunities for organic growth as well as growth through acquisition.”