04.03.19

With 95 employees, Van de Steeg, a member of the ASG Group (part of Atlas Holdings LLC) since 2011, made the transition to the growth market of packaging. Since 2012, it has been producing packaging for national and international customers from the beauty, perfume, and body care sectors. The old printing presses quickly reached their limits.

“We had a Heidelberg Speedmaster XL 105 in the Thalgau plant in Austria, and were very impressed with its quality and above all the short makeready times,” said Hermen Nassette, managing director of Van de Steeg in the Dutch city of Ensched. “Heidelberg has been looking after us as a global account for more than 10 years, and recommended exactly the right press for our new requirements – a Speedmaster XL 106 with six colors and double coating unit.”

Established in 1931, Van de Steeg started as a service provider for the textile industry. After its decline, the company focused on media printing. Together with the record label Polydor, the printing of album covers became a core business. With the introduction of CDs, Digipak media packaging was introduced and produced for major companies like Sony, Warner, and EMI. As this market diminished in the age of streaming services, Van de Steeg experienced strong growth in the cosmetics market. Today, high-end packaging makes up approximately 70% of Van de Steen’s business, while media printing accounts for 30%, marking a complete reversal.

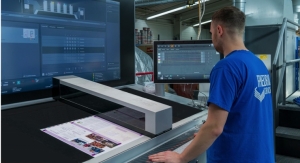

The Speedmaster XL 106 has been in operation in Enschede since the beginning of this year, replacing two competitor presses. Van de Steeg is now specializing in solid cardboard, finishing effects, and luxury packaging. With an average run length of 3,500 sheets per order and lots of job changes during three-shift operation, makeready time is an important subject. This is where the Hycolor Multidrive inking units and its parallel processes come in, greatly shortening makeready times. The press can be used for both UV and conventional printing, which delivers very high flexibility.

“Makeready is now quick and the print quality, as well as the reliability of the press, are first class,” said Nassette. “This press offers absolute added value and we have received exactly the right machine thanks to the comprehensive consultation.”

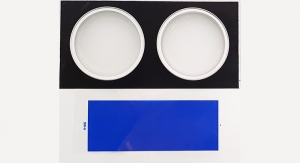

Van de Steeg specializes in high-end packaging in the luxury segment. It uses environmentally friendly packaging made from cardboard and soy- or water-based coatings. (Source: Heidelberg)

“We had a Heidelberg Speedmaster XL 105 in the Thalgau plant in Austria, and were very impressed with its quality and above all the short makeready times,” said Hermen Nassette, managing director of Van de Steeg in the Dutch city of Ensched. “Heidelberg has been looking after us as a global account for more than 10 years, and recommended exactly the right press for our new requirements – a Speedmaster XL 106 with six colors and double coating unit.”

Established in 1931, Van de Steeg started as a service provider for the textile industry. After its decline, the company focused on media printing. Together with the record label Polydor, the printing of album covers became a core business. With the introduction of CDs, Digipak media packaging was introduced and produced for major companies like Sony, Warner, and EMI. As this market diminished in the age of streaming services, Van de Steeg experienced strong growth in the cosmetics market. Today, high-end packaging makes up approximately 70% of Van de Steen’s business, while media printing accounts for 30%, marking a complete reversal.

The Speedmaster XL 106 has been in operation in Enschede since the beginning of this year, replacing two competitor presses. Van de Steeg is now specializing in solid cardboard, finishing effects, and luxury packaging. With an average run length of 3,500 sheets per order and lots of job changes during three-shift operation, makeready time is an important subject. This is where the Hycolor Multidrive inking units and its parallel processes come in, greatly shortening makeready times. The press can be used for both UV and conventional printing, which delivers very high flexibility.

“Makeready is now quick and the print quality, as well as the reliability of the press, are first class,” said Nassette. “This press offers absolute added value and we have received exactly the right machine thanks to the comprehensive consultation.”

Van de Steeg specializes in high-end packaging in the luxury segment. It uses environmentally friendly packaging made from cardboard and soy- or water-based coatings. (Source: Heidelberg)