10.10.18

Siegwerk will exhibit from Nov. 20-22 at this year’s InPrint Italy 2018. The company will present its customized inkjet ink and service portfolio, including its latest developments and innovations for digital printing. Siegwerk will present various application samples provided by customers and partners to demonstrate the wide-ranging possibilities of its inkjet ink solutions for personalized packaging and label applications.

Since its move into the inkjet ink area a few years ago, Siegwerk is today offering analog inks to printers and inkjet inks to equipment manufacturers both for packaging and label applications. The company attaches great importance to building long-lasting cooperation with business partners.

“With the right OEM and industry partners on our side, we are able to jointly shape the future of packaging printing and further drive inkjet printing for labels and packaging applications,” said Matthieu Carni, director Business Unit Inkjet at Siegwerk.

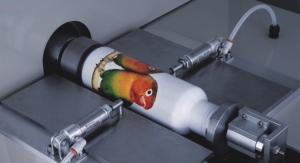

From the company’s perspective, UV and water-based inkjet are the most promising technologies. UV inkjet fits with narrow web printing on relatively thick material such as labels, direct-to-pack as well as aluminum blisters and offers good coding and marking options for packaging. UV inkjet inks offer clear benefits for narrow web single pass applications as they cure fast and can be quickly processed, are scratch- and abrasion-resistant and moreover create high-gloss prints ideal for label applications.

When looking at absorbent materials with a porous surface or very thin non-absorbent polymer films water-based inks are naturally offering great opportunities, making water-based inkjet the most promising inkjet technology for single pass large width printing on flexible packaging, tissue and corrugated applications.

Siegwerk’s inkjet offering includes UV inkjet solutions for both standard and sensitive applications as well as primers and OPVs suitable for several scopes. With Sicura NutriJet, the company, for example, provides an inkjet ink series for sensitive food and pharma packaging that works with different inkjet printing head technologies.

With Sicura Jet low-odor, Siegwerk offers the only non-CMR UV inkjet inks that are designed for printing labels for household, hygiene and industrial packaging, the company added.

All inkjet inks are suitable for a wide range of label applications like for example self-adhesive labels for cosmetics, wet-glue labels for food and beverages, direct to pack printing, blister packaging as well as aluminum lids for food products.

“We strongly believe that UV inkjet will become a mainstream printing technology for label applications and moreover expect some long-term opportunities for UV inkjet. especially in the direct-to-pack printing market,” Carni said. “Besides, we expect water-based inkjet to become the future technology of choice for digital printing of flexible packaging.”

Even though there are still some significant technological barriers and challenges that need to be overcome, Siegwerk is already working intensively on the development of water-based inkjet inks for packaging applications like flexible packaging, tissue or corrugated board for some time.

Siegwerk has continuously invested in the expansion of its digital printing segment and created a solid base for significant commercial success. Over the last three years, the company has invested several million euros to specially build up its development, production and testing capabilities in inkjet technology. After inaugurating a dedicated inkjet laboratory in 2016, Siegwerk introduced its first designated inkjet ink production facility in 2017.

Going forward, the company will continue to invest significantly in new equipment transforming its French site in Annemasse to the driving force for future inkjet ink solutions. With this year’s acquisition of AGFA’s UV inkjet ink subsection for single pass packaging and label inks, Siegwerk further extended its global reach in this young market segment.

The company doesn’t believe in “one fits all” solutions as every application requires different ink characteristics. That’s why Siegwerk offers customized ink solutions to the users’ concrete needs – adjusted to the final application and not only for a given printing equipment. For Siegwerk, customization goes beyond classical color matching; it also involves the optimization of adhesion, mechanical and chemical resistance properties as well as an assessment of migration risks.

Source: Siegwerk

Since its move into the inkjet ink area a few years ago, Siegwerk is today offering analog inks to printers and inkjet inks to equipment manufacturers both for packaging and label applications. The company attaches great importance to building long-lasting cooperation with business partners.

“With the right OEM and industry partners on our side, we are able to jointly shape the future of packaging printing and further drive inkjet printing for labels and packaging applications,” said Matthieu Carni, director Business Unit Inkjet at Siegwerk.

From the company’s perspective, UV and water-based inkjet are the most promising technologies. UV inkjet fits with narrow web printing on relatively thick material such as labels, direct-to-pack as well as aluminum blisters and offers good coding and marking options for packaging. UV inkjet inks offer clear benefits for narrow web single pass applications as they cure fast and can be quickly processed, are scratch- and abrasion-resistant and moreover create high-gloss prints ideal for label applications.

When looking at absorbent materials with a porous surface or very thin non-absorbent polymer films water-based inks are naturally offering great opportunities, making water-based inkjet the most promising inkjet technology for single pass large width printing on flexible packaging, tissue and corrugated applications.

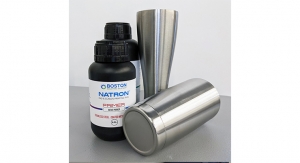

Siegwerk’s inkjet offering includes UV inkjet solutions for both standard and sensitive applications as well as primers and OPVs suitable for several scopes. With Sicura NutriJet, the company, for example, provides an inkjet ink series for sensitive food and pharma packaging that works with different inkjet printing head technologies.

With Sicura Jet low-odor, Siegwerk offers the only non-CMR UV inkjet inks that are designed for printing labels for household, hygiene and industrial packaging, the company added.

All inkjet inks are suitable for a wide range of label applications like for example self-adhesive labels for cosmetics, wet-glue labels for food and beverages, direct to pack printing, blister packaging as well as aluminum lids for food products.

“We strongly believe that UV inkjet will become a mainstream printing technology for label applications and moreover expect some long-term opportunities for UV inkjet. especially in the direct-to-pack printing market,” Carni said. “Besides, we expect water-based inkjet to become the future technology of choice for digital printing of flexible packaging.”

Even though there are still some significant technological barriers and challenges that need to be overcome, Siegwerk is already working intensively on the development of water-based inkjet inks for packaging applications like flexible packaging, tissue or corrugated board for some time.

Siegwerk has continuously invested in the expansion of its digital printing segment and created a solid base for significant commercial success. Over the last three years, the company has invested several million euros to specially build up its development, production and testing capabilities in inkjet technology. After inaugurating a dedicated inkjet laboratory in 2016, Siegwerk introduced its first designated inkjet ink production facility in 2017.

Going forward, the company will continue to invest significantly in new equipment transforming its French site in Annemasse to the driving force for future inkjet ink solutions. With this year’s acquisition of AGFA’s UV inkjet ink subsection for single pass packaging and label inks, Siegwerk further extended its global reach in this young market segment.

The company doesn’t believe in “one fits all” solutions as every application requires different ink characteristics. That’s why Siegwerk offers customized ink solutions to the users’ concrete needs – adjusted to the final application and not only for a given printing equipment. For Siegwerk, customization goes beyond classical color matching; it also involves the optimization of adhesion, mechanical and chemical resistance properties as well as an assessment of migration risks.

Source: Siegwerk