Mills And Mixers

Features

-

Breaking News | Mills and Mixers | New Products | Suppliers News

ROSS Develops Heavy-Duty Three Roll Mills for High Viscosity Dispersions

Features heavy-duty construction, precision workmanship and ANSI 2017-compliant controls package.02.01.23

-

Mills and Mixers | Suppliers News

The 2023 Ink Equipment Report

Equipment manufacturers see growth among inkjet, water-based ink customers.David Savastano, Editor 01.11.23

-

Breaking News | Mills and Mixers | New Products | Suppliers News

ROSS Highlights FDA-3500 Dual Shaft Mixer

Custom-built ROSS FDA-3500 has a maximum working capacity of 3,500 gallons.12.19.22

-

Breaking News | Mills and Mixers | New Products | Suppliers News

ROSS Highlights Model HSM-405SC-25 Inline High Shear Mixer

Mixer offers Solids/Liquid Injection Manifold (SLIM) Technology.11.30.22

-

Breaking News | Mills and Mixers | Suppliers News

ROSS’ Mixers.com Has a New Look

Mixers.com is faster, easier to navigate and contains more product information.11.16.22

-

Breaking News | Mills and Mixers | New Products | Suppliers News

Xtrutech Introduces New Clean-in-Place Feeder

The company has automated part of the cleaning process for the new feeder and hopper, with an automated CIP system suitable for all XTS production extruders.10.07.22

-

Breaking News | Mills and Mixers | Suppliers News

ROSS is Offering 3000-Gallon Multi-Shaft Mixers

Ideal for processing medium to high viscosity applications up to several hundred thousand centipoise.09.30.22

-

Breaking News | Market Research | Mills and Mixers

High Viscosity Mixer Market to Reach US$ 805.8 Million by 2022: Fact.MR

The global high viscosity mixer market is currently valued at US$438.3 million and is expected to expand at a CAGR of 6.3% between 2022 and 2032.09.19.22

-

Breaking News | Mills and Mixers | New Products | Suppliers News

Hockmeyer’s Nexgen Rotor Stator Optimizes Deagglomeration, Dispersion, and Particle Size Reduction

The patented technology achieves maximum particle deagglomeration and dispersion by combining mechanical and vacuum forces.08.30.22

-

Breaking News | Mills and Mixers | Suppliers News

Integrate Safety and Ergonomics in ROSS Ribbon Blenders

ROSS Ribbon Blenders meet OSHA standards with safety shaft guards and limit switches.08.17.22

-

Breaking News | Mills and Mixers | New Products | Suppliers News

ROSS Planetary Dual Dispersers Offer Unique Processing Flexibility

Offers excellent shear intensity and rapid dispersion of dry powders into viscous batches.07.01.22

-

Additives | Breaking News | Ink Manufacturers News | Metallics and Special Effects Pigments | Mills and Mixers | Personnel | Specialty Inks | Suppliers News

Dr. Tammo Boinowitz to Join Management Board of ALTANA AG

At the beginning of next year, Dr. Christoph Schlünken will hand over his Management Board responsibilities to Dr. Boinowitz.06.27.22

-

Breaking News | Mills and Mixers | New Products | Suppliers News

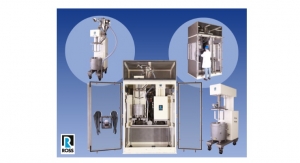

Ross Offers Fully Enclosed Mixing/Melting System

ROSS has the ability to completely engineer and customize a product from the ground up.06.06.22

-

Breaking News | Mills and Mixers | New Products | Suppliers News

ROSS Mixers Restored to Like-New Condition

Cost savings and faster shipping times allow companies to reach the profitable stage sooner.05.11.22

-

Breaking News | Distributor News | Mills and Mixers | Suppliers News | Testing, Color and QC

Vuletech Becomes Sole Agent for IM GROUP in Vietnam

Vuletech has been IM GROUP’s agent in Vietnam for the coating and special-projects segments since 202, and adds the ink segment.05.09.22

-

Breaking News | Mills and Mixers | Suppliers News

ROSS Offers 3000-Gallon Storage Vessels

Vessels are built and stamped according to ASME Section VIII Div 1.03.21.22

-

Breaking News | Mills and Mixers | Suppliers News

ROSS Offers Batch High Shear Mixers for Dispersions and Emulsions

Delivers powders in an efficient manner for quick wet-out and complete dispersion into low-viscosity liquids.02.25.22

-

Breaking News | Financial News | Mills and Mixers | Suppliers News

Milling Specialist Bühler Reports Strengthened Market Position in 2021

The company grew order intake by 16%, to more than CHF 3 billion ($3.24 billion).02.16.22

-

Breaking News | Mills and Mixers | Suppliers News

ROSS Video Celebrates 180 Years as OEM of Mixers

Film highlights commitment to client satisfaction, quality standards and longevity of ROSS mixers.02.08.22

-

Mills and Mixers | Suppliers News | Testing, Color and QC

Equipment Manufacturers are Seeing Growth in the Ink Industry

To meet the needs of their ink customers, equipment suppliers are developing new technologies.David Savastano, Editor 02.07.22