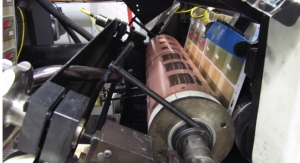

Flexography has definitely come into its own as one of the dominant printing processes, which has greatly impacted the ink business. Concerns about quality have been, and continue to be, addressed by ink and equipment suppliers. As a result, more ink manufacturers are developing higher quality inks and looking for ways to top their competition and create more opportunities within flexography.

To illustrate the promising future that flexo holds, consider the range of technologies being adopted by flexo printers. UV, EB and water-based technologies, still somewhat new and unproven in other market segments, have really caught on and gained market shares in flexo.

Ink World’s first feature article on flexography (July/August 1995) reported that the flexo ink market was worth $736 million. Today, Ink World estimates the flexographic ink segment to be quickly approaching the $1 billion mark, news that can mean great things for flexo ink manufacturers.

“Over the last several years, flexographic printing has shown worldwide growth. Continued growth can occur through an expansion of the market or through the capture of share from current rotogravure and offset business,” said Bob Mullen, vice president of packaging and inks, Sun Chemical Corporation. “To capture a larger share, flexo will need to continually improve the ability to print process colors and consistently show improvement with every impression and every job. Other print processes also will improve, keeping the competition keen. The print customer will be the beneficiary of this competition.”

Impacting the demand for new flexo inks will be the continued development of printing equipment. “We continue to see, especially in the narrow web 4-color process printing sector, a movement to even finer line anilox rolls, now in the range of 1000 lines per square inch,” said Gerald Napiecek, manager of technical services, No-Tox products, Colorcon. “This continues to put demands on ink makers to formulate inks which are stronger, transfer better from anilox to plate to substrate, and which will stay open, i.e. not dry prematurely in the anilox cells.”

“Since the evolution of digital plates, flexo printing is producing higher quality graphics and closing the gap to gravure printing,” said Kent Shah, vice president and chief technology officer, Color Converting Industries. “Therefore, there are more and more printers converting from gravure to flexo.”

Just how much flexo will continue to grow depends on print quality. “If the flexo process can ultimately match the offset printing quality, the demand for flexo will skyrocket,” said Jim Fried, product manager for fluid inks and coatings and director of export sales, Wikoff Color Corporation. “The quality is there in some areas, but the proof that it is not is evidenced by the ever increasing demand for multi-million dollar 6- and 8-color offset sheetfed presses.”

Growing Markets

Packaging continues to hold the most promise for flexographic printing. Within this segment, Mr. Mullen said increased demand has been seen for stand-up pouches, fresh-cut produce packages and medical packaging.

“In the corrugated market we have seen a demand for higher graphics within the typical brown box organizations,” said Grant Wishart, director of corporate services, Graphic Sciences. “In-plant ink blending systems continue to be a favorite choice for all the benefits they offer a converter. The ink kitchens, coupled with in-house technical service, has improved the efficiency of operations and brought up the standard for ink management in most box plants.”

Mr. Freid said the folding carton segment also offers growth opportunities for flexo ink suppliers. “As demand increases for cartons, the printers will look at their product mix and determine that it makes sense for them to grow in flexo rather than offset litho.”

In the narrow web label and packaging segment, Elizabeth Zinnbauer, global marketing communications manager, Akzo Nobel Inks, said there will be “continued demand for high quality graphics at reasonable prices delivered just in time in shorter and shorter run lengths.”

Food contact applications are another area showing promise in the flexo arena. “With the continued improvements in flexo’s ability to recreate graphics, especially at higher press speeds, food companies are finding flexo to be an economically attractive alternative to traditional offset printed promotions which they insert into their packages without an overwrap or other functional barrier,” said Mr. Napiecek. “These food companies also are finding that flexo inks, if formulated properly and dried properly after printing, can be less likely to affect the odor or taste characteristics of their foods than their offset counterparts.”

Colorcon recently unveiled its NT23 BR ink products, a new series of No-Tox direct food contact water-based flexo inks and coatings. According to Mr. Napiecek, this series can be used for printing applications where, traditionally, overwraps or functional barriers had to be used to adequately protect the food from migration of ink components. “Snack foods such as potato and corn chips are examples of foods where such barriers have traditionally been required,” he said.

|

Breakdown of Flexo Market

|

||

| Type of Ink | Million wet pounds | Percent annual growth |

| Water-based | 360 | 5 |

| Solvent-based | 195 | 3 |

| Rad-cure | 1 | 15 |

|

Source: Kusumgar, Nerlifi & Growney

|

||

Water-Based Inks

As ink manufacturers continue to look for new avenues within the flexo market, they are seeking out new markets for water-based products.

Among the end-use markets that ink manufacturers supply water-based products to are the paper and board segment, corrugated, multi-wall bags, household paper and preprint applications.

“In carton printing, there also has been growth in water-based flexo,” said Mr. Mullen. “In addition, the continued development of water-based technology has resulted in improvements in resolubility, a search for new surfactants and use of cleaner slow solvents for film laminations.”

While narrow web printers have used water-based products for quite some time, “we have seen more interest from wide web film printers in water-based inks, as part of companies’ overall goals of environmental protection and worker safety,” said Mr. Napiecek. “But there will continue to be a need for solvent inks in the wide web sector over the foreseeable future, at least in our opinion, particularly for those printers who have made significant investments in equipment to allow their companies to be in compliance with VOC emission regulations.”

“From the wide web perspective, there is a clear move towards water-based technology in wide web film printing,” said Niklas Olsson, global brand manager, Akzo Nobel Inks. “The ink technology is available for a limited range of substrates, mainly polyethylene and laminated films.”

Ink companies list environmental impact as one of the drivers for water-based products.

“Water-based inks have obvious advantages in the areas of VOC compliance, environmental safety, worker exposure safety, and in cost savings associated with shipping and storage as they are generally non-flammable materials,” said Mr. Napiecek. “As resin and additive technologies keep improving, the functional characteristics of water-based formulations will further challenge both solvent and energy-cured systems.”

“The challenge lies in that future growth will be in unsupported films, and to convert this with water-based flexo replacing solvent-based flexo,” said Mike Buystedt, product portfolio manager, Akzo Nobel Inks. “Everyone is looking for better water-based film inks.”

And although water-based inks offer significant environmental benefits, their success will not mean the demise of solvent-based flexo ink systems.

“Water-based flexo’s main advantage is significantly lower VOCs,” said Anthony Renzi, director of research and development, Sun Chemical Corporation. “However, I don’t see solvent use declining because of this advantage.”

According to Mr. Mullen, many large printers still run solvent inks by choosing incineration as the most practical method of complying with environmental regulations. “The print quality of solvent systems still makes them attractive.

“If the government abolished the use of alcohols and acetates, water-based systems would dominate,” continued Mr. Mullen. “Printers wish to avoid the capital outlay and running costs of incineration and recovery equipment associated with solvent-based inks. This makes low VOC ink systems that are compliant with environmental laws so attractive. These inks also could result in a substantial drop in insurance premiums or the need for construction of special rooms for handling solvent-based inks.”

The decision to use water-based or solvent-based inks could come down to cost issues. “For some printers there could be a cost of use advantage with water-based inks,” said Steve. D’Angelo, director of marketing, Flint Ink Corporation. “It really depends on the environmental issues at a given printing location. For a very small printer that does not have to capture or incinerate VOCs, solvent-based products would be less costly.”

UV/EB Technology

Ultraviolet and electron beam technologies continue to be a bright spot for the ink industry, and flexo printers are continuing to embrace rad-cure products.

“The UV/EB technology continues to be the most-asked-about technology by the flexible packaging printers,” said Brijesh Nigam, market manager for energy curing inks, Sun Chemical Corporation. “Narrow web label printers have successfully utilized this technology to gain a competitive edge in the marketplace. As far as the rest of the market’s concerned, printers are still looking for ways to utilize the technology.”

“From a quality standpoint, there is no question that UV flexo is the best flexo technology available, superior to both solvent-based and water-based flexo,” said Mr. Buystedt.

Deco-Chem recently introduced a new rotary screen ink that can be printed with either UV flexo, water-based flexo or other rotary screen flexo inks. “Rotary Label Plus (RLP) inks can be printed on top of flexo inks or other rotary screen inks, and printed under flexo or rotary screen inks; Rotary Flexo Plus (RFP) inks are specifically designed to be printed with RLP rotary screen inks,” said Eric Springer, marketing director, Deco-Chem. “These inks provide convenience to converters, allowing them to know which inks work well with rotary screen inks before putting them on press.”

Braden Sutphin Inks’ flexo division will introduce a new line of UV flexo and rotary screen inks in the first quarter that improve combination printing performance. “Our UV line features high strength, low viscosity and little or no silicon,” said John Samony, Sr., flexo division president, Braden Sutphin.

New from Wikoff Color is the Photo-Flex UV flexo ink series. “They have been well received in the market place,” said Mr. Freid. “Modifications of the basic formulas are needed for Arpeco presses, for example.”

Like other printing segments, however, continued R&D work is needed to address certain obstacles facing UV/EB flexo inks. “There are several challenges facing UV/EB technology in the packaging market. The most significant barrier is the technology’s inability to adapt the conventional press technology,” explained Mr. Nigam. “For example, it is relatively easy to utilize water in the place of the solvent inks. Printers normally do not require major capital investment or modifications to the press. In contrast, before a printer can utilize UV/EB technology, they must install curing equipment. This can require major capital investment, although the costs of this equipment are coming down.”

“The primary obstacle to stronger growth in radiation curable inks/coatings is cost – the raw materials are too expensive and the required equipment is still somewhat expensive,” added Mr. D’Angelo. “Currently, Flint Ink’s Rad Cure segment is enjoying better than average growth. However, I believe that it would be three to four times the average if material costs were more consistent with other ink materials.”

“There is an unbalanced requirement for lower and lower ink costs when today’s flexo inks save more material cost and improve productivity, which widely ‘pay for’ 5 percent higher ink cost,” said Mr. Olsson. “It’s hard to get converters to see the whole picture, that the total product cost (productivity, quality, rejects and resistance properties) are more important for their bottom line than 2 percent lower ink prices.”

Mr. Shah said that while UV/EB products are growing rapidly in the coatings market, inks are growing at a much slower rate, especially with wide web applications. “There are several reasons why the growth of UV/EB ink is slower, including the cost of equipment and inks,” said Mr. Shah. “Odor issues are still there for many food applications. I do not predict it will replace water-based or solvent-based inks in major markets.”

The Future of Flexo

Flexography definitely appears to have a bright future, which means good news for ink manufacturers. As more printers see the benefits of flexography over other printing processes and technological improvements continue, the flexo ink market will hit and easily surpass the $1 billion mark.

Mr. Shah identified two key trends continuing to drive the growth of flexography. “More and more printers are offering 10-color printing, which means they are offering better graphics through color separation,” said Mr. Shah. “Six-color process printing is getting more popular. This way the printers will have a wider variety of color reproduction.”

Helping to introduce printers to flexography has been the advent of combination presses.

“Combination printing is in-line utilization of various printing and converting processes in the narrow web label market,” said Mr. Nigam. “This may include any combination of water-based flexo, UV flexo, rotary screen, letterpress, offset, gravure, hot foil stamping, cold foil stamping and/or embossing. More and more converters are opting for UV flexo, UV rotary screen and hot stamp in-line operations.”

There is also the possibility of printers who currently use other printing processes adding flexography to their capabilities. “There is an indication that offset sheetfed printers are looking very hard at flexographic printing as an alternate or expansion to their business,” said Mr. Samony.

But no matter how much flexo continues to grow, cost will always be an overriding factor in the market’s development. “There is continued pressure from end-users on both the converters and ink manufacturers to reduce costs,” said Mr. Mullen. “As a result, there is a continued emphasis on examining both the printing and ink management processes.”

Recognizing how much potential exists for flexo inks, two ink companies made key acquisitions in the past year that will strengthen their position in this growing market.

Braden Sutphin acquired Roli Ink Company on Nov. 17. Roli Ink will be integrated into Braden Sutphin’s new flexo division. A full line of UV and water-based products are now available from the company for narrow web, wide web, folding cartons, corrugated and envelope, sheetfed, web heatset and forms printing applications.

Flint Ink’s major move of 2000 was its acquisition of the Alper Group. “The acquisition of the Alper Ink Group was a significant event for the flexo printing industry,” said Mr. D’Angelo. “Alper and Flint represented two of the largest flexo ink suppliers. The combination of products, segment expertise, and manufacturing assets is now very powerful. To be able to confidently offer products to such a diverse marketplace is quite an advantage.”

Many of the ink manufacturers that Ink World spoke with for this article said they expect to see continued consolidation among both printers and ink suppliers. According to Mr. Wishart, the industry might see more companies become involved in the flexo market over the next few years. “I think we will see ink companies that are not basic in flexo inks take a hard look at entering the market as environmental concerns continue to be a driving force behind the public’s demand for safer and more environmentally friendly manufacturing practices,” he said. “The market will follow the dollars and we will see a lot more ‘me-too’ companies that will copy existing ink systems and ride on the wings of the technological advancements of the core group of flexo ink manufacturers.”