Kerry Pianoforte, Ink World Associate Editor11.25.08

Despite challenging economic conditions and rising fuel and raw material costs, the metallic ink market

experienced continued, albeit moderate, growth during the past year.

“Metallic effects are increasingly popular,” said Rick Kistler, new business development – visual effects, inks and printing business line, for Ciba Corporation. “Eye catching graphics are becoming more important in packaging to attract consumers and create differentiation on the shelf – especially in today’s economy. As shrink sleeves become prevalent, using color on the entire package as an ‘advertising’ medium will also help grow these special effects.”

“Metallic effects in the graphic arts industry continues to grow at a modest rate,” Craig Reid, global head of marketing and business development, graphic arts, ECKART GmbH, said. “Metallic effects have significant shelf-appeal for designers and brand owners, and printing ink offers a cost effective, flexible solution to metallized substrates and transfer foils.”

Even with the difficult economy the ink market has been a growth market for Benda-Lutz. “With new aluminum products from newly installed state-of-the-art production lines, we expect to see further success in the ink industry,” said William Pofahl, vice president sales and marketing, Benda-Lutz.

Silberline has been witness to continued global growth in the demand for metallic pigments sold to the graphic ink market in 2008, “particularly for economic grades, and high-end grades that offer exceptional aesthetic value,” said Dr. Andrew Edwards, director – global inks market, Silberline.

“Overall, the 2008 metallic ink market is expected to be at the same level of 2007,” said John Adkin, European product director, sheetfed and UV, Sun Chemical.

“The overall usage of metallic pigments in traditional ink segments follow the downward trend of the market. However, we see metallic growth opportunities in other segments such as digital and security,” added Martha Davies, global product manager effect pigments, performance pigments, Sun Chemical.

Continually rising raw material and fuel prices have forced metallic pigment and ink suppliers to improve efficiencies and, in some cases, raise prices.

“The cost of utilities and most raw materials has risen dramatically in recent times, and this has meant that we have had to raise efficiencies with all products including metallics,” said Mr. Kistler. “Yes, the cost of aluminum is so far bucking the trend with respect to costs. However, if we look at all factors, including the increasingly populated competitive landscape, it is clear that here too we must raise efficiencies to thrive. We have taken steps to streamline our costs through lean manufacturing projects, process improvements, global sourcing, a certain amount of rationalization and vertical integration.”

“Everybody is being impacted by higher raw material prices and transport costs, which necessitated Silberline increasing our prices at the beginning of 2008,” said Dr. Edwards. “Every effort is made within the Silberline business to drive down cost while maintaining a high level of customer service and our excellent quality.”

“Higher raw material prices and the global economic situation is not good news; however, metallic printing ink still offers a cost effective alternative to foil and metallized substrates,” said Mr. Reid. “ECKART aims to provide a wide range of products to allow our customers flexibility to produce high quality cost effective print.”

“The cost of metals such as cooper, a need in the ‘gold’ or ‘bronze’ colors, has more than doubled since 2005,” said Mr. Adkin. “There are no alternatives available and we have been obliged to pass these extra costs on to our customers. The wholesale cost of metals, especially copper and aluminum, despite being a little volatile at the moment, are not expected to fall significantly in the months to come.”

“We have experienced the same market volatility as other suppliers in terms of raw material, energy and freight costs,” said Ms. Davies. “With the unusually high increase that we have had to accept, we have been pushed to pass at least a portion of the escalating costs through to the customers.”

Some manufacturers do see a light at the end of the tunnel. According to Mr. Pofahl, during the last year rising costs for raw material and energy have been significant issues. “But, by constant improvement of our production processes, we were able to avoid general price increases and so improved our competitiveness. Since the usage of metals like aluminum, copper and zinc is already doing down due to the general economic situation, the pressure on prices is not as big as some months ago, although prices for energy and labor are still increasing,” he added.

A key market for metallics is the graphic arts market. Used as a tool to differentiate a product or brand, metallic effects give packaging shelf appeal.

“The key market for metallic inks is packaging, where metallic effects can add significantly to the perceived value of the pack and the product,” said Mr. Adkin. “There is almost no limit to the attractive effects possible when using metallic effect pigments or integrating these metallic inks into different colors. Metallic effects add significantly to the shelf-appeal of many consumer products. Metallic effects also make an attractive alternative to bright plain colors in magazine cover designs.”

“Packaging and labeling are the key markets, specifically tobacco, beverage and cosmetics the big areas,” said Mr. Kistler. “In mold decoration and in mold labeling are also growth areas.”

“They key markets in graphic arts for metallics are tobacco packaging, flexible packaging, prime label and offset inks,” said Dr. Edwards. “In fact, all applications where a strong visual impact is required to help differentiate the end product are large users of metallic pigments and inks.”

Conductive inks is an emerging key area for metallics. “Overall this market is growing,” said Mr. Kistler. “The big growth was to have been RFID antennae, however this remains a small proportion of the overall conductive ink market, and in some cases, antennae production has even moved away from printing.”

“Currently a lot of development work is being done on this sector and we see big potential for conductive inks,” said Mr. Pofahl. “One example is printing of RFID antennas. So far, all of the products we are offering are tailor-made for our customers’ specific needs.”

Understanding technical and formulation requirements is one key challenge metallic ink suppliers must face. “Some of the key challenges are to supply products which fit the individual needs of printers, be it print speed, substrate, surface or reverse, required resistance etc.,” said Mr. Kistler. “Specifically for aluminum VMP pigments, some of the challenges are to supply products with universal appeal allowing usage in different solvent and resin systems. Quality-wise we have advantages with some of the brightest and unique looks on the market.”

“There is a trend toward finer pigments with improved brilliance and higher coverage,” said Mr. Pofahl. “Production of fine brilliant non-leafing pigments is especially technically challenging.” Another challenge, according to Mr. Pofahl, is improved stabilization technologies for water-based and UV-curing systems to reduce the amount of VOCs.

“Stability remains the main technical challenge, but the drive towards faster press speeds and lower ink consumption while maintaining bright metallic effects is also a challenge,” said Mr. Reid.

Metallic inks can be supplied as one-pack ready to use or two-pack, mix before use products. “One challenge for the ink maker is the preparation of a ready-to-use product with long shelf-life with no loss of brilliance or opacity due to tarnishing on storage,” said Mr. Adkin.

“The key technical challenges with metallic inks and pigments are the shelf life of both the ink and pigment, the ability to prevent tarnishing, the ease of use/formulation flexibility and the balancing cost versus performance to maximize the brilliance in end-use application,” added Ms. Davies.

Expectations for the future are cautiously optimistic, as a result of the continued economic slowdown.

“As does everybody else, we expect a slowdown of the global economy for the next year, but nevertheless we expect to see an increase for metallic pigments,” said Walter Sauseng, research scientist at Benda-Lutz Werke. “Especially for Benda-Lutz, there are lots of possibilities for expansion by entering new markets. Benda-Lutz manufactures metallic pigments only, not finished ink systems. With recent consolidation among pigment suppliers, this is an advantage for our customers.”

“With the drama going on with the global economy, 2009 is likely to be a very turbulent year,” said Dr. Edwards. “However, there are many reasons to be positive moving into 2009, and the forecast from key customers look very good; 2009 will be another exciting step forward for Silberline’s graphic arts and printing ink division.”

“We expect to see a continued growth in the use of metallic effect pigments,” said Mr. Kistler. “There will also be some new and interesting products coming through Ciba including UV curable VMP inks. We also look to innovative new uses for metallic inks.”

Sun Chemical reports metallic inks sales are expected to be approximately the same as the sales level in 2007 and 2008. “It is an exciting time for Sun Chemical’s performance pigments group as we position ourselves to launch into metallic pigments, offering our customers a complete product portfolio of organic and metallic pigments,” said Ms. Davies.

“We expect 2009 to be a very tough year due to the global economic situation and increasing raw material prices, but remain positive that we can offer a range of special effects to suit a wide market section, thereby offsetting slow markets demand with more active areas,” Mr. Reid concluded.

|

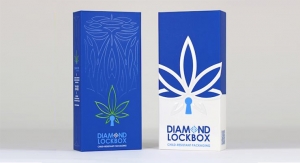

Photo courtesy of ECKART. |

“Metallic effects are increasingly popular,” said Rick Kistler, new business development – visual effects, inks and printing business line, for Ciba Corporation. “Eye catching graphics are becoming more important in packaging to attract consumers and create differentiation on the shelf – especially in today’s economy. As shrink sleeves become prevalent, using color on the entire package as an ‘advertising’ medium will also help grow these special effects.”

“Metallic effects in the graphic arts industry continues to grow at a modest rate,” Craig Reid, global head of marketing and business development, graphic arts, ECKART GmbH, said. “Metallic effects have significant shelf-appeal for designers and brand owners, and printing ink offers a cost effective, flexible solution to metallized substrates and transfer foils.”

Even with the difficult economy the ink market has been a growth market for Benda-Lutz. “With new aluminum products from newly installed state-of-the-art production lines, we expect to see further success in the ink industry,” said William Pofahl, vice president sales and marketing, Benda-Lutz.

Silberline has been witness to continued global growth in the demand for metallic pigments sold to the graphic ink market in 2008, “particularly for economic grades, and high-end grades that offer exceptional aesthetic value,” said Dr. Andrew Edwards, director – global inks market, Silberline.

“Overall, the 2008 metallic ink market is expected to be at the same level of 2007,” said John Adkin, European product director, sheetfed and UV, Sun Chemical.

“The overall usage of metallic pigments in traditional ink segments follow the downward trend of the market. However, we see metallic growth opportunities in other segments such as digital and security,” added Martha Davies, global product manager effect pigments, performance pigments, Sun Chemical.

Continually rising raw material and fuel prices have forced metallic pigment and ink suppliers to improve efficiencies and, in some cases, raise prices.

“The cost of utilities and most raw materials has risen dramatically in recent times, and this has meant that we have had to raise efficiencies with all products including metallics,” said Mr. Kistler. “Yes, the cost of aluminum is so far bucking the trend with respect to costs. However, if we look at all factors, including the increasingly populated competitive landscape, it is clear that here too we must raise efficiencies to thrive. We have taken steps to streamline our costs through lean manufacturing projects, process improvements, global sourcing, a certain amount of rationalization and vertical integration.”

“Everybody is being impacted by higher raw material prices and transport costs, which necessitated Silberline increasing our prices at the beginning of 2008,” said Dr. Edwards. “Every effort is made within the Silberline business to drive down cost while maintaining a high level of customer service and our excellent quality.”

“Higher raw material prices and the global economic situation is not good news; however, metallic printing ink still offers a cost effective alternative to foil and metallized substrates,” said Mr. Reid. “ECKART aims to provide a wide range of products to allow our customers flexibility to produce high quality cost effective print.”

“The cost of metals such as cooper, a need in the ‘gold’ or ‘bronze’ colors, has more than doubled since 2005,” said Mr. Adkin. “There are no alternatives available and we have been obliged to pass these extra costs on to our customers. The wholesale cost of metals, especially copper and aluminum, despite being a little volatile at the moment, are not expected to fall significantly in the months to come.”

“We have experienced the same market volatility as other suppliers in terms of raw material, energy and freight costs,” said Ms. Davies. “With the unusually high increase that we have had to accept, we have been pushed to pass at least a portion of the escalating costs through to the customers.”

Some manufacturers do see a light at the end of the tunnel. According to Mr. Pofahl, during the last year rising costs for raw material and energy have been significant issues. “But, by constant improvement of our production processes, we were able to avoid general price increases and so improved our competitiveness. Since the usage of metals like aluminum, copper and zinc is already doing down due to the general economic situation, the pressure on prices is not as big as some months ago, although prices for energy and labor are still increasing,” he added.

The Graphic Arts Market

A key market for metallics is the graphic arts market. Used as a tool to differentiate a product or brand, metallic effects give packaging shelf appeal.

“The key market for metallic inks is packaging, where metallic effects can add significantly to the perceived value of the pack and the product,” said Mr. Adkin. “There is almost no limit to the attractive effects possible when using metallic effect pigments or integrating these metallic inks into different colors. Metallic effects add significantly to the shelf-appeal of many consumer products. Metallic effects also make an attractive alternative to bright plain colors in magazine cover designs.”

“Packaging and labeling are the key markets, specifically tobacco, beverage and cosmetics the big areas,” said Mr. Kistler. “In mold decoration and in mold labeling are also growth areas.”

“They key markets in graphic arts for metallics are tobacco packaging, flexible packaging, prime label and offset inks,” said Dr. Edwards. “In fact, all applications where a strong visual impact is required to help differentiate the end product are large users of metallic pigments and inks.”

Conductive inks is an emerging key area for metallics. “Overall this market is growing,” said Mr. Kistler. “The big growth was to have been RFID antennae, however this remains a small proportion of the overall conductive ink market, and in some cases, antennae production has even moved away from printing.”

“Currently a lot of development work is being done on this sector and we see big potential for conductive inks,” said Mr. Pofahl. “One example is printing of RFID antennas. So far, all of the products we are offering are tailor-made for our customers’ specific needs.”

Understanding technical and formulation requirements is one key challenge metallic ink suppliers must face. “Some of the key challenges are to supply products which fit the individual needs of printers, be it print speed, substrate, surface or reverse, required resistance etc.,” said Mr. Kistler. “Specifically for aluminum VMP pigments, some of the challenges are to supply products with universal appeal allowing usage in different solvent and resin systems. Quality-wise we have advantages with some of the brightest and unique looks on the market.”

“There is a trend toward finer pigments with improved brilliance and higher coverage,” said Mr. Pofahl. “Production of fine brilliant non-leafing pigments is especially technically challenging.” Another challenge, according to Mr. Pofahl, is improved stabilization technologies for water-based and UV-curing systems to reduce the amount of VOCs.

“Stability remains the main technical challenge, but the drive towards faster press speeds and lower ink consumption while maintaining bright metallic effects is also a challenge,” said Mr. Reid.

Metallic inks can be supplied as one-pack ready to use or two-pack, mix before use products. “One challenge for the ink maker is the preparation of a ready-to-use product with long shelf-life with no loss of brilliance or opacity due to tarnishing on storage,” said Mr. Adkin.

“The key technical challenges with metallic inks and pigments are the shelf life of both the ink and pigment, the ability to prevent tarnishing, the ease of use/formulation flexibility and the balancing cost versus performance to maximize the brilliance in end-use application,” added Ms. Davies.

Expectations for the future are cautiously optimistic, as a result of the continued economic slowdown.

“As does everybody else, we expect a slowdown of the global economy for the next year, but nevertheless we expect to see an increase for metallic pigments,” said Walter Sauseng, research scientist at Benda-Lutz Werke. “Especially for Benda-Lutz, there are lots of possibilities for expansion by entering new markets. Benda-Lutz manufactures metallic pigments only, not finished ink systems. With recent consolidation among pigment suppliers, this is an advantage for our customers.”

“With the drama going on with the global economy, 2009 is likely to be a very turbulent year,” said Dr. Edwards. “However, there are many reasons to be positive moving into 2009, and the forecast from key customers look very good; 2009 will be another exciting step forward for Silberline’s graphic arts and printing ink division.”

“We expect to see a continued growth in the use of metallic effect pigments,” said Mr. Kistler. “There will also be some new and interesting products coming through Ciba including UV curable VMP inks. We also look to innovative new uses for metallic inks.”

Sun Chemical reports metallic inks sales are expected to be approximately the same as the sales level in 2007 and 2008. “It is an exciting time for Sun Chemical’s performance pigments group as we position ourselves to launch into metallic pigments, offering our customers a complete product portfolio of organic and metallic pigments,” said Ms. Davies.

“We expect 2009 to be a very tough year due to the global economic situation and increasing raw material prices, but remain positive that we can offer a range of special effects to suit a wide market section, thereby offsetting slow markets demand with more active areas,” Mr. Reid concluded.