Sean Milmo, Ink World European Editor09.12.05

In some areas, however, persuading European printers to take initiatives in saving money is a hard task. This is particularly the case if they have to invest in new equipment which will not generate an immediate return.

Ink companies are well positioned to help printers, for example, to eliminate wasteful use of inks by ensuring they apply the right amount for specific jobs.

Often these sort of productivity gains can be achieved only through the installation of a dispensing system, backed by software for automated control and measuring devices.

Ink makers are trying to facilitate the purchasing of the dispensing equipment by offering a variety of financial plans as part of their customer services programs. Some dispensing systems are sold by ink companies under their own labels as part of long-term ink supply agreements. The price of the equipment is then incorporated into the price of the ink so that the payment is spread over a period.

Even with the availability of these incentives, ink management is not at the top of the list of priorities for many European printers, who can see better means for boosting their profitability.

“Despite the many discounts and other funding arrangements around at the moment, printers still find this dispensing equipment to be too expensive,” said Avon Joyce, technical director at the U.K. ink company Bousfield Ltd., Bristol, England.

“In today’s economic climate, ink management for printers is not easy,” he added. “It is regarded as being a bit of a luxury which needs a buoyant market to take full advantage of.”

Nonetheless, printers are not disinterested in the issue. Thus, for dispensing system manufacturers and the ink companies which often distribute and market the equipment, the challenge is to make printers realize that even in the present harsh times, effective ink management is worthwhile.

“Printers will listen to sensible suggestions,” said Mr. Joyce. “You cannot force them to go down a particular track. Instead, you have to listen to what they want and then respond to their requirements.”

“Maybe their first objective is to have a clean and efficient print shop,” he continued. “At the moment, the measuring and monitoring of the ink may not be so important to them.”

A major obstacle to the spread of dispensing systems in Europe is the relative lack of concern about ink waste among printers. They are far more worried about wasting paper.

“Inks make up less than 5 percent of a printer’s total costs, whereas with paper it can be as much as half,” said one ink sales manager. “Inevitably, printers are much more clearly focused on the need to save paper.”

The matter of ink waste tends to receive much less attention than in the U.S., where different ways of formulating inks lead to faster drying times.

“The message about cutting ink waste does not carry so much weight in Europe,” said Chris Dillon, European operation manager at the U.K.-based subsidiary of Accel Graphic Systems Inc., Dallas, manufacturers of the Sentinel cartridge dispensing systems.

“Levels of ink wastage are lower in Europe because the ink does not dry so quickly in the ducts nor skin so rapidly in containers,” he added.

Because of this, dispensing systems have a higher penetration in the U.S. While an estimated 30 percent to 35 percent of larger format U.S. printers now use cartridge equipment, the proportion in Europe is thought to be less than a third of that. Small- and medium-sized European printers are even less enthusiastic.

The marketing efforts of dispensing equipment manufacturers, ink companies and their distributors in Europe are being undermined by the apparent absence of a clear-cut advantage of one system over another.

Printers with long runs such as magazines favor using barrels, usually in excess of 25 kilograms, from which the ink is pumped to the presses. Then there is the option of vacuum packs, from which inks can be dispensed directly onto the press and which can cut down waste as much as cartridges.

Cartridges Move Forward

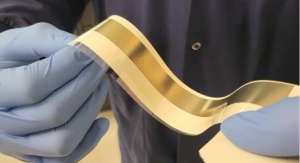

Still, most experts seem to agree that the future lies with cartridges, which are even beginning to displace pumping systems among some major printers in Europe. Cartridges are mounted on guide rails above the printing unit and have a microprocessor-controlled monitoring and application system. Among printers with small- and mid-sized presses, the ink can be dispensed through pneumatic cartridge guns.

One of the main arguments in support of cartridges is that they can reduce make-ready and changeover times. However, printers complain about their high capital expense and that on long runs, they can actually increase the rate of changeovers.

“It is not very surprising that in an industry notorious for its conservatism, printers prefer to stick to the traditional dispensing of pouring ink straight from the tin into the duct,” said an ink company marketing executive.

A key benefit of cartridges, which the two leading manufacturers, technotrans AG, Sassenberg, Germany, and Accel, believe will work increasingly to their advantage is color consistency.

Cartridges eliminate the problem of fluctuations in color when ink ducts run short or are being refilled.

“Some presses are better at hiding this difficulty with color lifts than others, but it usually takes quite a few sheets before the fluctuation is levelled out,” said Mr. Dillon. “A cartridge device is necessary to gain proper control over the color flow.”

Accel’s Sentinel cartridges, which have a 3.6 kg capacity against technotrans’ 2 kg, have electronic sensors which track and report ink usage.

“Our system tells the printer exactly how much is being used for each job,” said Mr. Dillon. “Printers know how much they spend on ink and even how much they throw away, but most don’t know how much is actually being applied on the press.”

Ink management is not necessarily all about cutting costs within the printing process. The disposing of ink containers and discarded ink and the need to comply with Europe’s relatively strict environmental regulations also need to be taken into account.

In areas like Scandinavia, the Benelux states and countries such as Germany and Austria, which tend to have the strictest environmental rules, disposing of ink packaging can be expensive.

“There are not only big differences in disposal costs between countries but even between cities within individual states,” said Maarten Snel, a technical consultant at Van Son, Hilversum, Netherlands. “Here in Holland the variation in disposal costs between cities can be as much as fivefold.”

In the U.K., where waste regulations are based on EU legislation, containers are classified as general waste if the ink residues are less than 1 percent of the container’s weight or are completely dried, according to Bousfield.

Otherwise, they are classified as special waste, which needs to be put in a bulk container and disposed by a registered contractor in a landfill site or by incineration. Ink ‘skins’ which have been removed from their original containers are categorized as special waste.

Containers with special waste have to be clearly labeled and correctly sealed, with full descriptions of the waste being given to the contractor.

Van Son markets a 1 kilogram cardboard cartridge, developed with the help of De Ruiter Packaging, Heino, Netherlands, a specialist in ink dosing and other delivery systems.

The small size of the cartridge, half that of the conventional 2 kg dispenser, helps printers applying special colors reduce waste. The paper packaging means that disposal costs are much lower than with a plastic cartridge.

Sales of the cartridge have been growing slowly since its launch around 10 years ago. But it is a slow procedure winning over printers in the target sheetfed market, where cartridges have still failed to make major inroads in Europe.

“Interest among printers in the cartridge depends a lot on the environmental pressures they are facing, which mostly depend on where they are located,” said Mr. Snel.

In its marketing of the cartridge, Van Son combines its environmental usefulness with its ability to reduce ink waste. “The cartridge appeals to printers who have a lot of short runs with a frequent change of colors,” Mr. Snel explained. “It saves ink, especially by avoiding skinning in ducts and containers.”

Van Son believes that when small amounts of ink are taken from a standard tin container over a lengthy period, skinning can take up as much as 85 percent of ink.

Sellers of dispensing systems tend to have to convey specific messages for different senior executives in European printing companies because of a lack of a single convincing advantage.

“You need to make separate presentations to the production manager about cleanliness and other efficiencies, to the environment manager about ease of disposal and to the finance director about overall cost savings,” said Mr. Dillon. “Once all three of these are won over, you might gain an order.”

However, European sales of dispensing systems are likely to remain stagnant until there is an economic upturn and a recovery in the printing market. Even then there may have to be a new surge in investment in new equipment, because most new presses now incorporate dispensing systems.

“This is a sector which will be driven to some extent by the purchasing of new presses,” said Mr. Dillon. “Printers then see what is to be gained from cartridge systems and will retrofit them into their existing presses.”