11.30.11

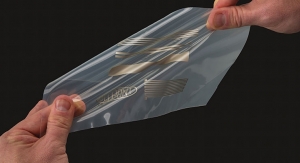

NovaCentrix announced that Metalon ICI-021, the newest copper-based screen ink in the ICI series, is now available for shipment and is being featured at Printed Electronics USA 2011 in Santa Clara, CA from Nov. 30-Dec. 2, 2011. Pre-printed samples of Metalon ICI-021 screen ink on card stock are on-hand at the NovaCentrix exhibit, and can be converted to copper with the PulseForge 3300 tool also on exhibit in the booth.

The ICI-021 formulation improves in several key areas upon the ground-breaking ICI-020 ink. The ICI-021 ink achieves sheet resistance as low at 16 milliohms/sq and has improved handling and print properties versus the ICI-020. Like its predecessor, it is also optimized for use on standard paper and cardstock materials.

Importantly, this ink is still based on the use of very-low cost copper oxide, enabling a sampling price of $100/100g and contracted volume selling price as low as $75/kg.

“The ICI-021 ink is consistent with the NovaCentrix emphasis on economical performance,” said Stan Farnsworth, vice president marketing. “Market response to the ICI-020 has been very strong, and the new ICI-021 ink improves key performance attributes while keeping the cost exceptionally low.”

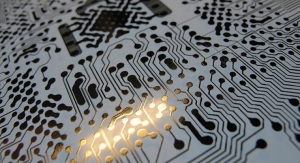

The Metalon ICI series of inks are formulated with copper-oxide nanoparticles along with a reduction agent, in water. After the ink is printed, a PulseForge tool is used to drive a reduction reaction, thereby converting the copper oxide into a thin film of highly conductive copper. Importantly, this process is performed in ambient air on low temperature substrates at speeds exceeding 100 meters/minute.

The ICI inks have received awards and recognition including being named were named a recipient of “Top Three 2010 Innovations” from the coatings association AIMCAL, received an R&D 100 award in 2010, and received recognition in 2009 from printed electronics analyst and consultant group IDTechEx as a top materials innovation. The inks are available in formulations for most print methods, including screen, inkjet, flexographic, gravure and aerosol.

The ICI-021 formulation improves in several key areas upon the ground-breaking ICI-020 ink. The ICI-021 ink achieves sheet resistance as low at 16 milliohms/sq and has improved handling and print properties versus the ICI-020. Like its predecessor, it is also optimized for use on standard paper and cardstock materials.

Importantly, this ink is still based on the use of very-low cost copper oxide, enabling a sampling price of $100/100g and contracted volume selling price as low as $75/kg.

“The ICI-021 ink is consistent with the NovaCentrix emphasis on economical performance,” said Stan Farnsworth, vice president marketing. “Market response to the ICI-020 has been very strong, and the new ICI-021 ink improves key performance attributes while keeping the cost exceptionally low.”

The Metalon ICI series of inks are formulated with copper-oxide nanoparticles along with a reduction agent, in water. After the ink is printed, a PulseForge tool is used to drive a reduction reaction, thereby converting the copper oxide into a thin film of highly conductive copper. Importantly, this process is performed in ambient air on low temperature substrates at speeds exceeding 100 meters/minute.

The ICI inks have received awards and recognition including being named were named a recipient of “Top Three 2010 Innovations” from the coatings association AIMCAL, received an R&D 100 award in 2010, and received recognition in 2009 from printed electronics analyst and consultant group IDTechEx as a top materials innovation. The inks are available in formulations for most print methods, including screen, inkjet, flexographic, gravure and aerosol.